Treatment Plant Pump Cavitation Causing Pump and Pipe Vibration

A county water treatment plant heard "cavitation-like noise" from their newly installed pumps and called MSI for help. Specialized vibration testing was conducted to see if damaging cavitation existed and how to best address the issue.

- Problem Statement (Challenge)

- What (type of machine): Water Treatment Plant Horizontal Split Case Pumps

- Where (State/ Country): Michigan

- Why (problem/reason): Cavitation noise coming from the newly installed pumps had the customer worried. An attempt to change the suction pipe configuration and put straightener vanes in front of the pump suction did not help.

- Work Performed

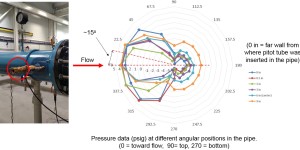

- Vibration Testing Methods: Experimental Modal Analysis (EMA), Condition Monitoring, Operating Deflection Shape (ODS), and Flow Traverse Pressure Readings to identify swirl flow at the suction nozzle of the pump.

- Results/ Solution

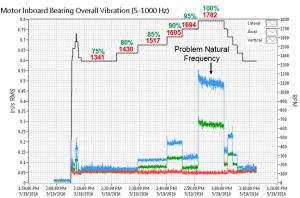

- Findings: The flow traverse test on the suction piping revealed that the flow profile entering the pump was skewed and was the main reason for cavitation within the pump swirl flow). Pictures taken of the impeller showed signs of cavitation damage. There was also a motor natural frequency within the operating speed range.

- Impact: The findings suggested that the suction piping design needed to be modified in order to eliminate the skewed velocity profile causing the cavitation. A Computational Fluid Dynamic Analysis calibrated to the data collected on site was recommended to the customer. The CFD would help in the development of a solution to the flow problem with a greater chance of success upon implementation A motor pedestal redesign was recommended to shift the structural natural frequency above the running speed range

Prior to MSI's involvement, others attempted piping modifications on a trial and error basis. Both consumed time and money but did not prove to be successful.

Click image to animate.

MSI's flow traverse testing port and results

Picture of cavitation damage on impeller.

Overall vibration trend plot showing the motor natural frequency going into resonance at a certain speed.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.