MSI Sentry® Automated Diagnostics

Developed for the AEDC under SBIR Program

Customizing Sentry®, MSI is able to build monitoring solutions for your unique machines & applications

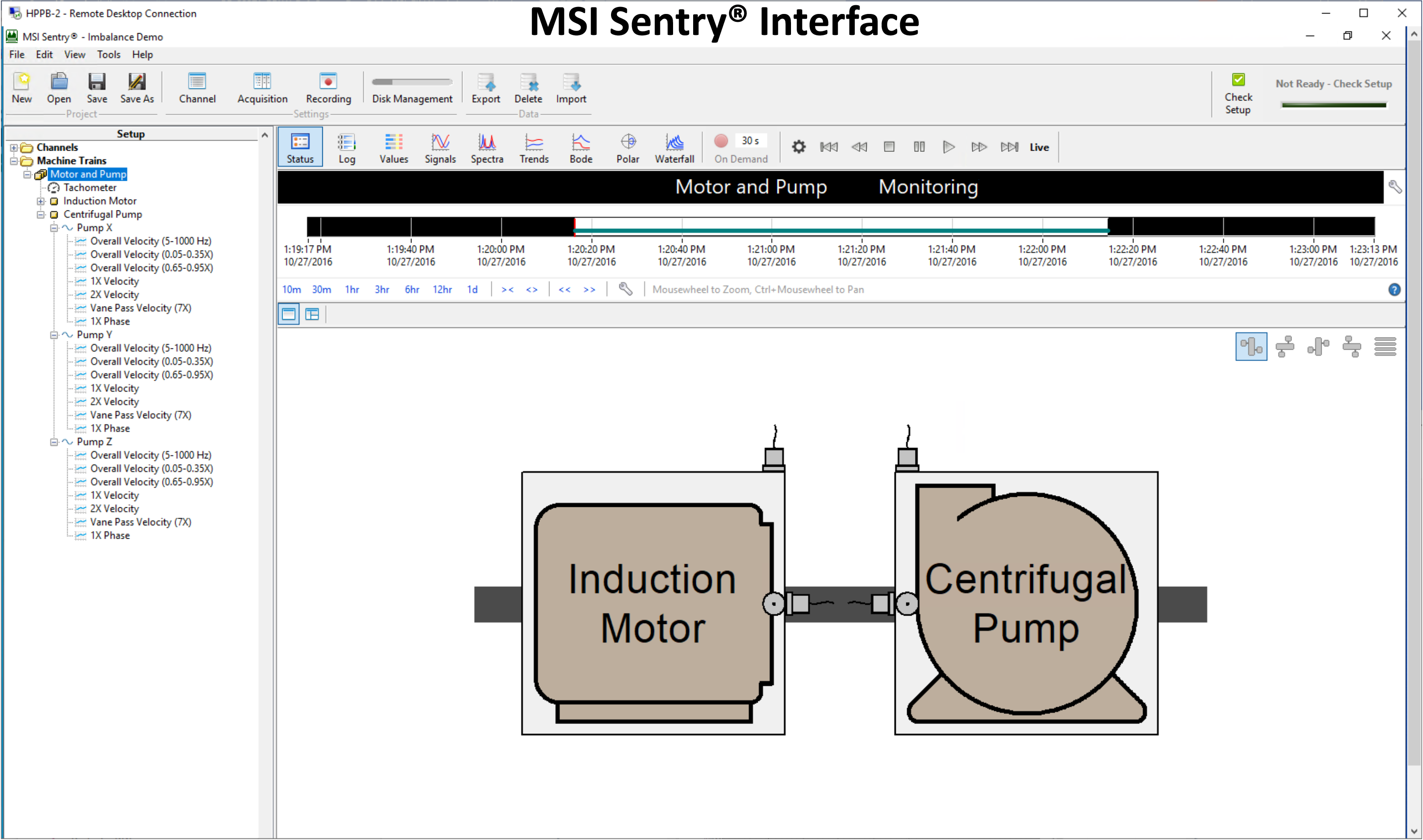

Sentry® is based on MSI’s machinery diagnostic approach developed for plants and for the military. It is able to be merged with MSI’s VibVue® high-speed video motion magnification system, built around an algorithm licensed from the U.S. top engineering university.

Sentry® accurately diagnoses critical faults, combining info from custom low-cost sensors with any existing sensors. Added to this is knowledge of the machine design and experience, so there is no need to “train” the system.

MSI engineers are machinery design experts, with decades of experience. They thoroughly understand how machines work, and most importantly, how they fail.

Sentry® makes real-time design-based machine health recommendations, accelerating decision-making.

Sentry® represents over a decade of development for the U.S. military, and decades of MSI troubleshooting experience.

The Output of Sentry®

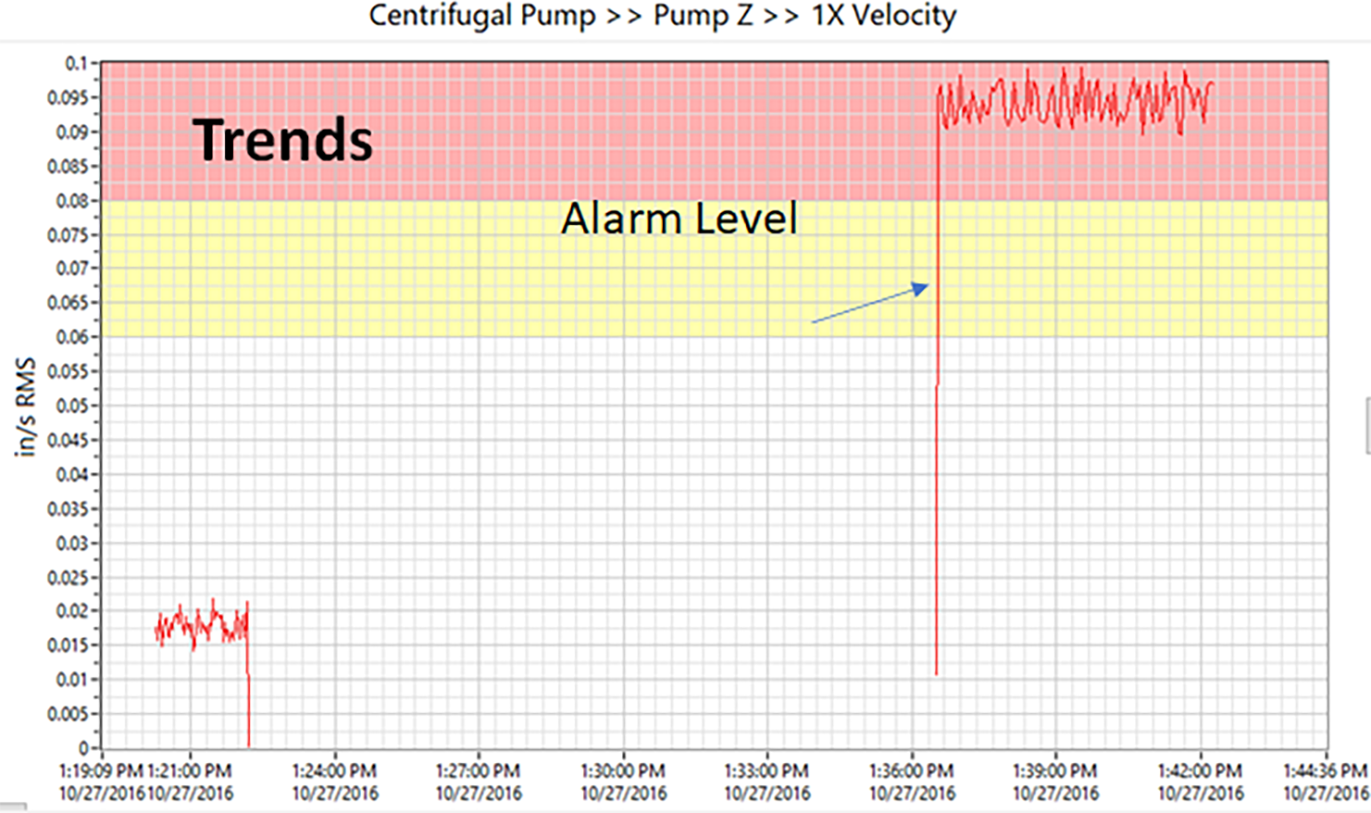

Output begins with “green light/ red light” to flag impending or existing problems.

Output is easy to understand, and is augmented by pictorial diagnostic messages.

Detailed fault diagnostics can be presented in plain text with recommended solutions, within a user-friendly interface that is customized by MSI for individual solutions.

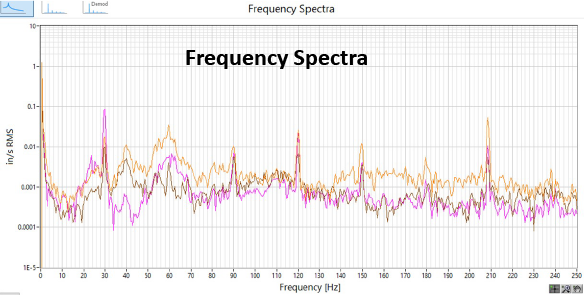

If wanted, user can obtain a shock waveform or FFT frequency spectra.

MSI provides optional vibration video software that makes each pixel a motion/vibration sensor.

Optional full-scene high-speed video magnifies motion 1000x and displays vibration to 2 microns.

Therefore: Sentry® supports various levels of output detail, depending on user requirements.

Sentry® is able to tie into existing condition monitoring systems, or can be stand-alone.

Sentry® Covered Machinery

MSI has experience developing and deploying physics-based, highly configurable, user-friendly machinery health management systems for critical service rotating machinery and balance of plant equipment. These systems can be used for permanently installed condition-based maintenance and predictive health monitoring, as well as for temporarily installed troubleshooting and fault diagnostics. Sentry® supports these machinery types:

Sentry® Automated Machine Condition Monitoring Targeting Problems

Using vision-based physics-based understanding of common failure modes in rotating machinery, MSI can automate the diagnostics of your machinery. Using the appropriate instrumentation and signal analysis techniques, we can configure your system to identify any of the following conditions: