We Love Solving Problems

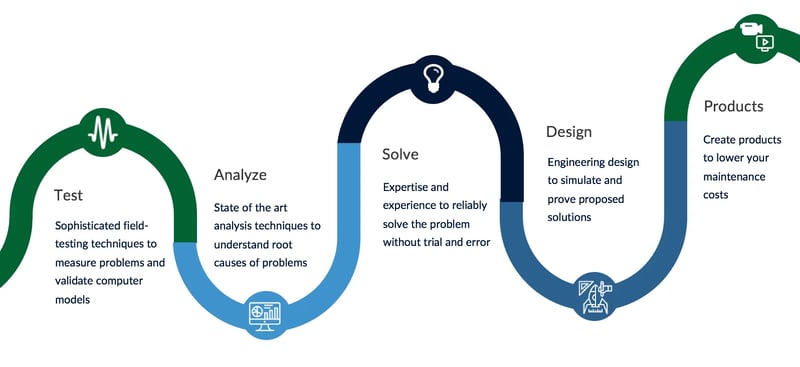

MSI Reliably Resolves Vibration & Dynamics Problems in Rotating Machinery Through Test, Analyze, Solve, Design, and Support.

WE WORK AS AN EXTENSION OF YOUR TEAM

MSI teams resolve problems, starting at any point in the test, analyze, solve, design process.

FIELD-BASED TESTING, MONITORING AND TROUBLESHOOTING

Sophisticated Field Testing

Avoid the costly and chronic trial and error approach to problem solving with sophisticated field-testing techniques to characterize problems, validate computer models, and find the root cause of the problem. MSI troubleshooting consultants' specialized testing, monitoring and troubleshooting capabilities include:

- Advanced vibration analysis and diagnostics

- Operating deflection shape (ODS) testing

- Video vibration magnification testing (VibVue®)

- Time-Averaged Pulse (TAP™) “bump” testing during operation

- Dynamic pressure testing

- Strain gauge testing

- Torsional testing/telemetry

- Rotating machinery performance - pressure, flow, cavitation, efficiency, & temperature

- Blade vibration and high cycle fatigue - blade deflection & strain

- Experimental modal analysis - Impact hammer & shaker excitation

- Machinery test stands

- Bladed disk “SAFE” or Interference diagrams from impact (ring) testing and/or FEA evaluations

FIND THE REAL PROBLEM

State-of-the-Art Analysis

MSI has more than $2M invested in state-of-the-art design, analysis, and testing tools and techniques to understand root causes of problems. Techniques used include the following, but see Engineered Design section below for a list of software and other tools used:

- Rotordynamics & Torsional Analysis

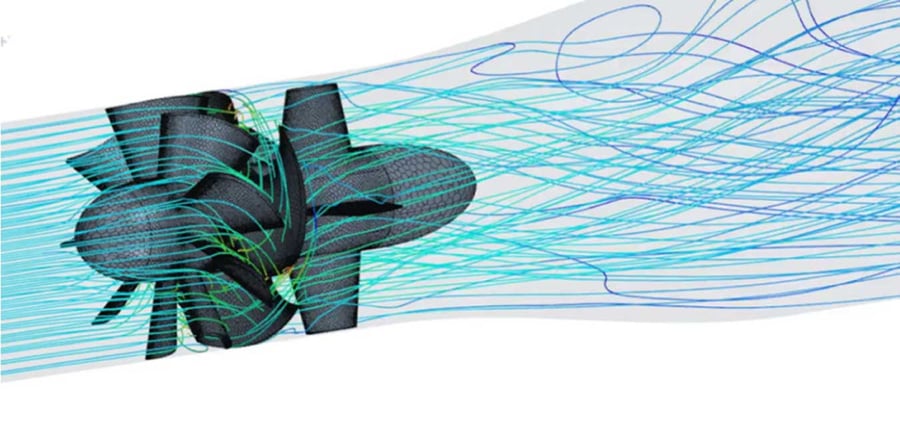

- Fluid Flow/CFD, Transient Heat Transfer, Fluid/Structure Interaction (FSI)

- Tribology (Friction and Wear Optimization, Bearing and Seal Design)

- Finite Element Stress, Deformation, Thermal, Shock & Vibration Analysis

- Nonlinear Dynamics & Plasticity Analysis

- Machinery Development Support – Complete Machines or Components

USING EXPERTISE AND EXPERIENCE

Reliably Solve Problems

With over 28 years of resolving vibration and dynamics issues for a variety of rotating machinery, including pumps, compressors, fans, blowers, gearboxes, and motors, MSI has a reputation for reliably solving even the most difficult vibration, dynamics or performance problems based on:

- The testing and analytical capabilities listed above to solve dynamic problems, and analyze new designs

- Staff selected and trained to perform both office-based computational analysis and advanced field-based testing to find the real problem

Here are some of MSI’s memberships, credentials and certifications:

- Member API 610, 612, and 617 Machinery Committees

- Texas A&M Turbo & Pump Symposium Advisory Committee

- The first Hydraulic Institute Standards Partner (2018 award)

- Vibration Institute Members and Lecturers

- ISO TC108 Machinery Diagnostic Standards Committee (USA voting member)

- ASTM Fatigue & Wear Standards Committees since 1984

FIX THE PROBLEM

Engineered Design

Design and simulation to prove proposed solutions is essential to achieve right first-time every time resolution of problems. Software and other tools used include:

- ANSYS FEA - Full Multiphysics Version, with Heat Transfer & Fluid Flow plus LS Dyna Add-on for Penetration Analysis

- ANSYS CFD and STAR-CCM+ CFD

- ROMAC RotorLab Rotordynamics/ Bearing/ Seal

- CFturbo Axial/Mixed Flow/Radial Turbomachinery Design

- CompAERO and TurbAERO Axial and Radial Turbomachinery Design and Analysis

- Generalized Fluid System Simulation Program (GFSSP)

- Pro/Engineer Wildfire Solid Modeler

- Siemens NX

- SolidWorks

- SDRC FEmap Model Meshing Tool

- ME-Scope Shock & Vibration Test Visualization with full Vibration & Acoustics

- NIST ACTIS Tribology Computer Program Set

- Developing & Applying Foil Bearings

- Prototype & Rig Construction, Operation

CREATE PRODUCTS TO LOWER MAINTENANCE COSTS

Products to Enable Your Team

.webp?width=470&height=313&name=Albany%20test%202(1).webp)

MSI has created a variety of tools that it uses in its Testing, Analyzing, Solving and Design services. Some of these advanced technology tools are also available to you for purchase, along with training and support for your Reliability and Maintenance Engineers. The key benefit is lower maintenance costs by enabling your team to use some of the same tools MSI applies.

YOUR PROBLEMS RELIABLY SOLVED

Solutions Customized to Find and Fix your Problem, Explanations and Recommendations in Plain English

Depending on your needs, MSI can deliver one or more discrete component or end-to-end solutions over the lifetime of your equipment. Customized solutions can include any, or all, of the above capabilities and always include a jargon-less, clear report explaining all key findings and making detailed fix recommendations.

“MSI does a great job - always very helpful. Gone through many problems with them - everything handed to them they've solved.“- Craig Miller, Pump & Process Equipment Specialist, Atlantic Equipment