Design Assessments Lower Risk and Cost

By Preventing Potential Problems With Rotating Machinery Prior to Installation of the Equipment in a Plant.

WHOLE SYSTEM ANALYSIS

Conducted by an Independent Third Party

Design Assessments are usually conducted by third parties to ensure independent assessment of a design prior to building and installing it. With a professional review conducted by an independent specialist, the interaction between components from various vendors can be accounted for, in addition to confirming that the proposed design meets all necessary specifications and standards. A design assessment often takes multiple iterations and can be part of a design process to incorporate specialty or new components or conditions.

A design assessment gives the customer and the OEM increased confidence and assurance that preventable problems will not be built-in or installed. Examples from MSI’s experience include an unproven 3rd stage of an ethylene compressor, a high NSS pump suction impeller, multiple guaranteed flow rates, unusually low specified vibration acceptance criteria, and a new rotating machine design without installation history.

DRAFT YOUR RFP WITH THE ASSESSOR’S HELP

How to Setup a Design Assessment

Include a Design Assessment in Your Project RFP

Set your OEM supplier(s) expectations for a design assessment as part of the specifications, process, schedule, and cost of the project.

Select the Right Assessor(s)

Ensure your selections have good reputations with OEM suppliers and industry-specific peers for doing thorough design assessments collaboratively.

Specify Your Specialist Design Assessor(s)

List one or more specialist companies as selected and trusted partners to conduct the design assessment.

Why Do Design Assessments?

Avoid Building or Installing Problems

Installing preventable problems leads to unexpected delays and additional costs

Mitigate Project Risk

Ensure project schedules and start-up are not delayed

Select the Right Assessor

You’ve decided to do a design assessment. The next critical decision is who will conduct it? Choose MSI for systems that include rotating equipment.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Plant Expansion / Revamp Evaluations

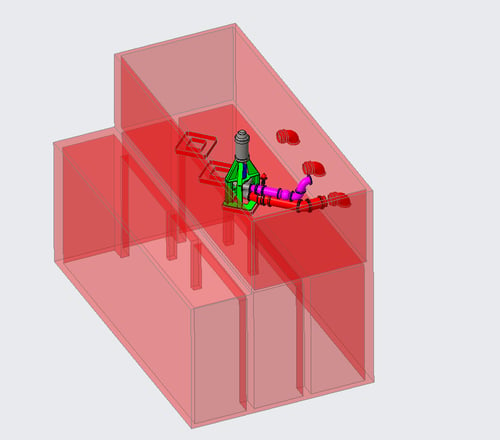

MSI provides plant operators and engineering firms with analysis services to validate how new or retrofitted machinery and plant configurations will perform to avoid post-installation issues once the system is installed and operational .

Case Study

Design Assessment Mitigates Risk

A design assessment was carried out in an effort to prevent potential premature bladed disk and impeller fatigue failures of three newly installed critical compressor trains.

Case Study

Pre-Construction Analysis for Singapore’s Marina Barrage

MSI performed pre-construction analysis on Singapore's major flood control installation to check for life-limiting vibration problems.