Machinery and Systems

Our Engineering Consultants Prevent, or Pinpoint and Resolve Vibration Problems in Rotating Machines.

Supported Machinery and Systems

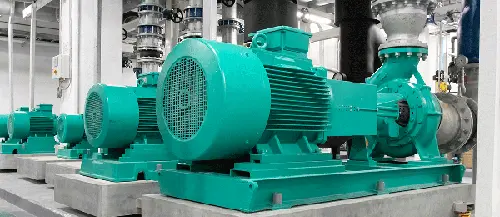

Our engineering consultants specialize in pumps, compressors, turbines, expanders, piping, and pressure vessels. MSI staff have worked for both OEMs and end-users alike, and have an extensive background supporting all rotating machinery and their related systems.

MSI always considers the machine as part of a system, including components such as the foundation, the piping network, associated valves, the process fluid, and everything associated with the successful operation of the machine. Our comprehensive test and analysis techniques help tell the whole story on what’s wrong, and how to make it right.

EXAMPLES OF WHAT WE DO

Our Expertise: Rotating Machinery

Centrifugal and Axial Pumps (any size/HP)

- Power plant pump systems for a variety of fuel types including natural gas, nuclear, concentrated solar, biomass, waste heat, and coal

- Oil and gas for upstream, mid-stream, and refining applications

- Pumps that are critical to water, waste water, and flood control infrastructure

- Petrochemical and ammonia plants

- Mass produced consumer products such as dishwasher pumps, pool pumps, automotive engine coolant pumps, and pumps related to the HVAC industry

- Bio-medical applications including both adult and pediatric heart pumps

- Rocket engine turbopumps and aircraft engine fuel pumps

- Niche applications such as a high pressure pump design for energy recovery

Centrifugal and Axial Compressors (all sizes/HP)

- Oil and gas for upstream, mid-stream, and refining applications

- Equipment used by the air separation industry, especially integrally geared compressors

- Power plant Induced Draft and Forced Draft fans and water treatment aeration blowers

- HVACR refrigeration, air conditioning and heat pump compressors

- Plant air compressors

- Fuel cell blowers, turbochargers, and superchargers

- Street sweeper applications

- Niche applications such as an FAA approved blower design for a commercial aircraft toilet

Axial and Radial Turbines & Expanders

- Hydraulic turbine generators for the power industry

- Large steam turbine generators, aeroderivative gas turbines, and geothermal turbines in the power industry

- Multistage and single stage steam turbines, as well as aeroderivative gas turbines used to drive pumps and compressors in the power, oil and gas, and other industries

- Waste-to- energy and energy recovery radial and axial turbines

- Wind turbine gear boxes and ocean wave turbines

- Aircraft and drone gas turbine engines

- Industrial products such as high-speed air turbines for drilling tools (manufacturing and dental)

- Niche applications such as a mass produced hydraulic turbine to recover energy from rest room facility water flow

Piping & Pressure Vessels

While MSI is often called upon to solve challenging vibration problems with rotating machinery, successful diagnosis and resolution often requires evaluation of the complete system, including the piping and pressure vessels. Often, the excess vibration captures the attention of the operators, while the underlying root cause is later found to involve the piping. MSI has the necessary instrumentation and data acquisition expertise to measure pressures and strains in these systems, along with the advanced analytic capabilities to predict these values. Our experience allows us to compare experimental against analytic results to uncover the thorniest issues in industrial systems.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Pump System Seismic Structural Analysis

Mechanical Solutions, Inc. (MSI) was contracted by a manufacturer to perform a seismic structural analysis on three identical large pump systems in a low-activity and high-activity nuclear waste treatment process.

Case Study

Nuclear Generator Stator Cooling Pumps Specialized Vibration Testing

A nuclear power plant’s generator stator cooling pumps had experienced random elevated vibrations during steady conditions since their installation in the 1980s.

Case Study

Steam Generator Feed Pump Vibration and Pipe Strain Testing

Staff at a nuclear power plant was trying to understand why their new feed water pumps exhibited high vibration and showed step changes over time with inconsistent alignment behavior.