Product Development as a Service

MSI Develops Software and Hardware Solutions Based on Proven Expertise for a Variety of Applications.

SOFTWARE, HARDWARE, OR BOTH

MSI Product Development Capabilities

MSI has a wealth of product design and development experience to leverage for your business:

- Design and development of turbomachinery under orders from industrial and governmental customers, where deliverables include tested prototype hardware and the engineering package required for production.

- Oil-free foil bearing development, production, and technology transfer for customers' turbomachinery applications.

- Software development and consultancy for a wide range of testing and measurement applications, with a particular emphasis on Machine Auto Diagnostics

- Developing and integrating high-speed video and multi-dimensional spatial tracking technology into new or existing products.

Whether you’re developing a product from scratch, need extra resources to meet a deadline, or overcome a technical hurdle, we can help.

Turbomachinery Development

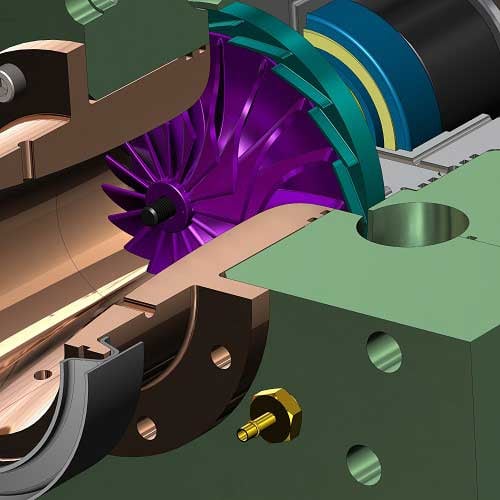

MSI designs, sources, assembles, and tests pump, compressor, and turbine components and complete machines in support of machinery manufacturers and system integrators. MSI’s decades of high-speed refrigeration compressors is most recently focused on systems using emerging low Global Warming Potential (GWP) refrigerants.

Learn More About Turbomachinery DevelopmentLow Global Warming Potential (GWP) Compressors

MSI possesses extensive experience in developing high-speed centrifugal compressors, especially those that use refrigerants as the working fluid. For example, MSI has been at the forefront of developing more environmentally friendly compressors and heat pumps with significantly lower global warming potential (GWP).

Learn More About Low Global Warming Potential (GWP) CompressorsHigh-Speed Video & 3D Spatial Tracking

We offer high-speed video and 3D spatial tracking to characterize, track, and analyze objects in motion for a wide variety of applications.

Learn More About High-Speed Video & 3D Spatial TrackingMachinery Auto Diagnostics

MSI’s engineers are uniquely positioned to lead the industry shift to autonomous machine condition monitoring with custom, physics-based solutions.

Learn More About Machinery Auto DiagnosticsFoil Bearings Development

Our foil bearings offer performance & efficiency unmatched by conventional bearings for high-speed, oil-free turbomachinery systems.

Learn More About Foil Bearings DevelopmentMODULES AND SYSTEMS

MSI Solutions

CoMAT

This solution provides prediction of steady state and transient fluid structure interaction under fluid loads, thermal loads, structural deflection, vibration, and dynamic effects.

Distance Communication Maintenance System (DCoMS)

DCoMS is the eyes and ears of remote field-based troubleshooting, where secure multiple video feeds, two-way audio and text enable remote and rapid problem resolution.

Galvanic Corrosion ANSYS® Module

This module uses CAD and FEA models to output galvanic corrosion couples, alerting designers to potential corrosion, and enabling design iterations to avoid corrosion problems.

GSX™ Blade Failure Detection Hardware and Software

MSI’s patented non-contacting (microwave radar) stress measurement system (NSMS) provides accurate blade vibration, stress, and failure detection for gas and steam turbine blades.

HELPING YOU SUCCEED

Product Development Goals

To help customers achieve their unique and challenging design objectives as efficiently and effectively as we can.

To represent, explain and discuss our findings and recommendations in plain English, avoiding technical jargon mystifying customers.

To design optimal components, such as lubrication-free foil bearings that offer performance and efficiency unmatched by conventional bearings for high-speed turbo machinery.

To incorporate our system-level approach in all of our designs, such as a heat pump supercharger based on funded research MSI developed a high-speed centrifugal compressor for use in cold climate heat pumps.

To employ typical and advanced vibration sensors - radar sensors for advanced measurement in compressor and turbine blades, helicopter rotors, cavitation, & ceramic bearings.