Computational Fluid Dynamics Services (CFD) & Consulting

Computational Fluid Dynamics (CFD)

Unsteady CFD Services, Consulting, and Products Focused on Solving Customer Design Problems

COMPUTATIONAL FLUID DYNAMICS

For New or Improved Designs and Troubleshooting

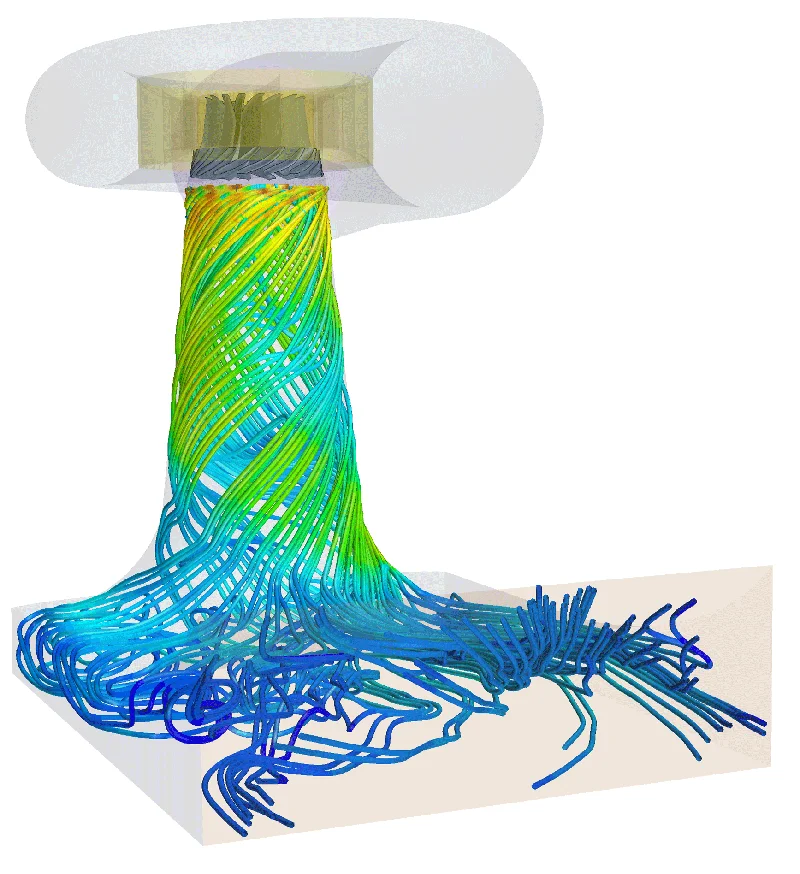

Whether designing a system from scratch, optimizing a design, or troubleshooting an existing flowpath, MSI provides unsteady (transient) solutions to evaluate and optimize pressure and velocity fields and analyze flow and performance.

Typical problems involve Multiphase, Transonic, & Supersonic Conditions; Non-Newtonian Fluids; and Large Temperature Gradients.

MSI has extensive experience analyzing new designs and existing machine system flowpaths, piping systems, and more to optimize performance for OEMs, government, and commercial end-users.

MSI also sells, supports, and provides training for Simcenter STAR-CCM+ from Siemens.

Contact us or subscribe to our blog.

CFD Expertise and Analysis Tools

CFD Leadership

MSI CFD services are led by industry-renowned engineer and MSI Vice President of Fluids Engineering, Ed Bennett, Ph.D.

The Most Effective CFD Software Tools

MSI CFD software analysis tools include STAR-CCM+ and ANSYS/CFX. Our preliminary analysis tools include CFturbo, CompAero, TurbAero, FGSSP, and more.

Combination CFD and FEA

MSI frequently combines CFD and FEA analysis to solve fluid structure interaction (FSI) vibration and dynamics problems.

CFD Calibrated to the Real World

MSI uses field test data and experience to calibrate CFD models and analyses to real-world conditions to validate predictions.

What is Computational Fluid Dynamics (CFD)?

CFD is a branch of fluid mechanics that uses numerical analysis and data structures to analyze and solve problems that involve fluid flows. Computers are used to perform the calculations required to simulate the free-stream flow of the fluid, and the interaction of the fluid (liquids and gases) with surfaces defined by boundary conditions.

With high-speed supercomputers, better solutions can be achieved, and are often required to solve the largest and most complex problems. The latest software has improved the accuracy and speed of complex simulation scenarios such as transonic or turbulent flows.

The fundamental basis of almost all CFD problems are the Navier–Stokes equations, which define many single-phase (gas or liquid, but not both) fluid flows. These equations can be simplified by removing terms describing viscous actions to yield the Euler equations. Further simplification, by removing terms describing vorticity yields the full potential equations. Finally, for small perturbations in subsonic and supersonic flows (not transonic or hypersonic) these equations can be linearized to yield the linearized potential equations.

CFD Benefits

Our CFD capabilities and tools produce analysis in absolute terms for relevant, real-world predictions, not just relative A-B comparisons.

MSI uses CFD to evaluate and understand fluid behaviors pertinent to a problem – very few companies use CFD for troubleshooting.

MSI uses field test data to calibrate CFD and FEA models and analyses to real-world conditions to validate predictions.

Once behaviors are understood and validated, we simulate potential optimized designs or remedies. This saves time and money by avoiding trial and error implementation with right-first-time designs and fixes.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Acceptance Criteria For Your Sump Pump With Our Optimized Inlet Piping Designs

Acceptance criteria for sump pump with optimized inlet piping designs: Pumps are often in awkward places with limited space to design long straight inlet pipes. Bends and Valves upstream can disturb the flow which can significantly compromise pump performance and reliability.

Case Study

Ultra-Low Head Hydro Turbine Design Optimization

The customer approached MSI during the design phase of their project looking for assistance with improving an existing hydro turbine design for ultra-low head hydropower applications.

Case Study

Reconciling Predicted Hydro Turbine Results to Test Stand Performance

MSI was tasked with resolving the discrepancy between test stand results and predicted performance for a new hydro turbine design.