Development Of A Vacuum Blower

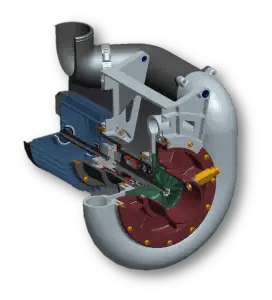

MSI was contracted by a major aerospace equipment supplier/manufacturer to design and prototype an FAA-approved vacuum generator for use on commercial aircraft. The design would be subject to strict FAA requirements and RTCA environmental conditions/test procedures for airborne equipment. At the customer's request, MSI studied the failure modes of the competitors' products. In collaboration with the customer, a low pressure ratio single-stage centrifugal blower design was selected with a high-speed electric motor drive. The design requirements included strict size and weight restrictions as well as aggressive duty cycle and life requirements.

As part of the development process, MSI used many of the analysis tools in its toolbox, including:

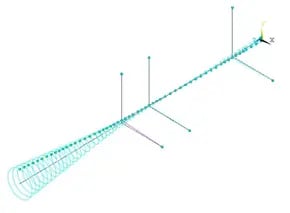

- rotordynamics analysis

- coupled thermal/structural conjugate heat transfer analysis'

- fluid structure interaction (FSI)

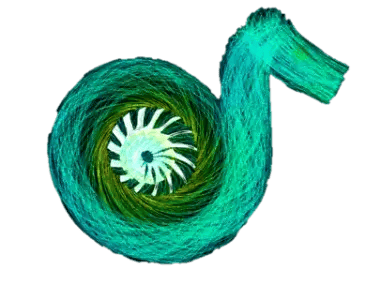

- computational fluid dynamics (CFD) analysis

- fatigue life analysis

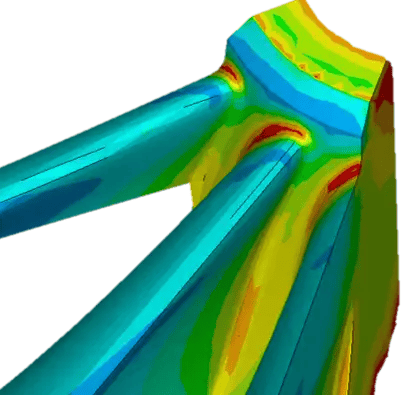

- structural analysis including non-linear material behavior and contact

- modal analysis

- transient electromagnetic analysis

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.