Foil Bearing Development

Hydrodynamic (Self-Acting) Compliant Foil Bearings Generate Their Own Load-Carrying Film From the Rotation of the Shaft It Supports.

USE THE PROCESS GAS TO GENERATE LIFT

MSI’s Hydrodynamic Compliant Foil Bearings

MSI’s hydrodynamic (self-acting) compliant foil bearings generate their load-carrying film from the rotation of the shaft it supports. A smooth top foil forms the bearing surface, and a flexible “bump” foil provides this surface with controlled, resilient support.

This proprietary design ensures a “self-adjusting” bearing with inherent internal damping that adapts to shaft misalignment, variations due to tolerance buildups, centrifugal and thermal shaft growth, and differential thermal expansion. Large or small, our foil bearings can provide the performance you need for specialized high-speed or extreme-temperature machinery.

Example Foil Bearing Applications

Air-Cycle Machines

This common foil bearing application provides oil-free air for high-speed systems such as fuel cell blowers and turbochargers.

High-Speed Motors

With the advent of higher-speed drivers, foil bearings let you run as fast as rotordynamics will allow.

Oil-Free Compressors

For compressors involved in heat exchange, eliminating lubricant from the process improves thermal performance, such as HVAC and cryogenic applications.

Gas Turbines

High-temperature-capable materials and coatings facilitate lubricant free bearing support for combustion systems.

Custom Foil Bearing Designs for Your Application

Whether you need a new design or retrofit to an existing machine, our experts will analyze, design, and manufacture foil bearings tailored to the unique rotordynamics of your machine and its application. We have a library of designs to start from, and can often utilize an existing design if the application is somewhat flexible. We will always work with our customers to determine what makes the most sense for them.

MSI has decades of experience designing, building and testing foil bearings for a wide variety of systems, including for rotating machines that we design ourselves. Because of this, we can support our customers with as much or as little of their machinery development effort as they like, from conceptual design to prototype testing.

We are very flexible in terms of technology transfer. We realize bearings are literally supporting YOUR idea, and not the other way around. We have a wide variety of technology transfer and manufacturing options to support getting your solution to market.

THE BEARING SOLUTION YOU NEED

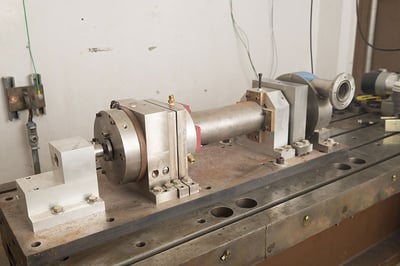

Our Unique Approach to Foil Bearing Development

Foil bearings offer performance and efficiency unmatched by conventional bearings for high-speed machinery.

Our foil bearing engineers help develop rotating machinery systems, so they understand your needs.

Our flexible approach to technology transfer and manufacturing options help you get your idea to market.

MSI’s hybrid hydrostatic/hydrodynamic bearing solutions provide more lift for applications that require it.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Solids Handling Pump Repetitive Failure of Bearing and Seal

An engineering construction firm needed help in determining the root cause for the repetitive pump bearing and seal failures of a solids handling pump and to provide a solution to eliminate the issue.

Case Study

Design Assessment Mitigates Risk

A design assessment was carried out in an effort to prevent potential premature bladed disk and impeller fatigue failures of three newly installed critical compressor trains.

Case Study

Development of a Prototype Vacuum Blower

A major aerospace equipment supplier/manufacturer needed to design and prototype an FAA-approved vacuum generator for use on commercial aircraft.