Solids Handling Pump Repetitive Failure Of Bearing And Seal

An engineering construction firm needed help in determining the root cause for the repetitive pump bearing and seal failures of a solids handling pump and to provide a solution to eliminate the issue. The new pumps were installed to increase the capacity of the wastewater facility.

- Problem Statement (Challenge)

- What (type of machine): Main Raw Sewage Influent Centrifugal Bottom Suction Solids Handling Pump

- Where (State/ Country): New York

- Why (problem/reason): An engineering construction firm needed help in determining the root cause for the repetitive pump bearing and seal failures of a solids handling pump and to provide a solution to eliminate the issue. The new pumps were installed to increase the capacity of the facility. The plant had various tests performed to address the questioning about the piping modifications implemented to retrofit the new pumps. MSI was called to conduct specialized vibration testing on the pump systems and help avoid dealing with future problems.

- Work Performed

- Results/ Solution

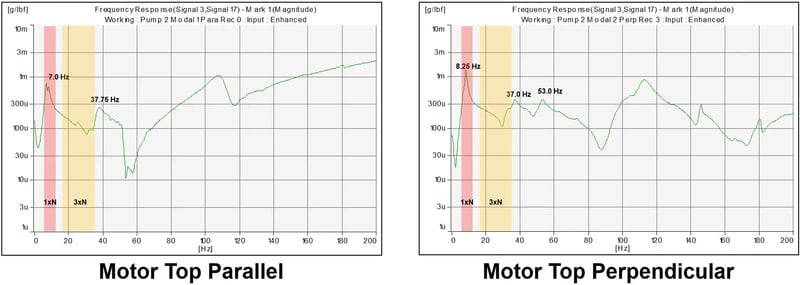

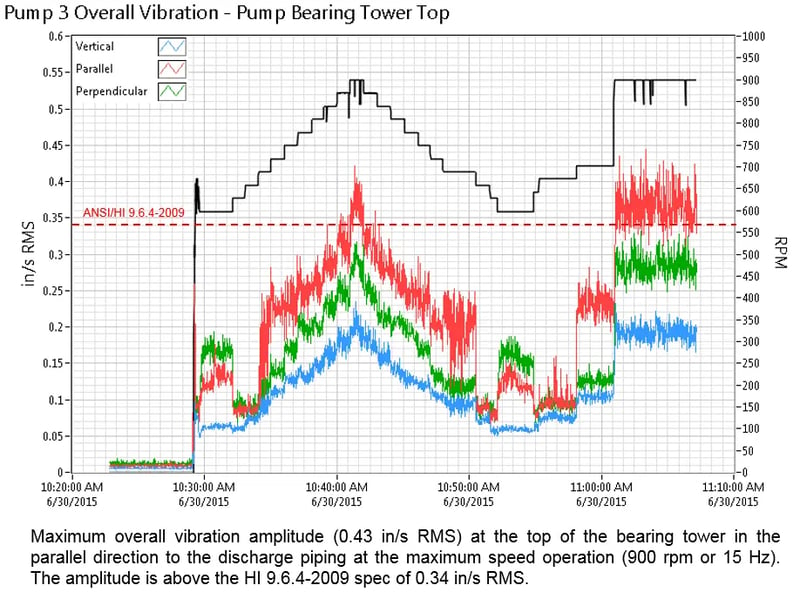

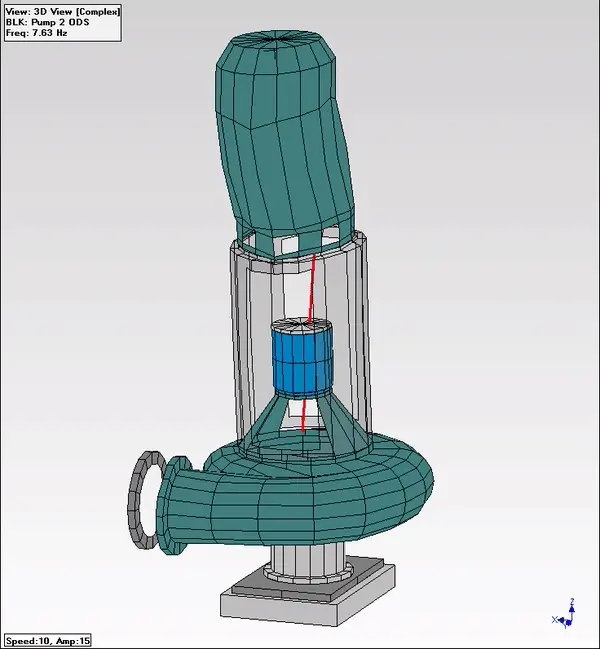

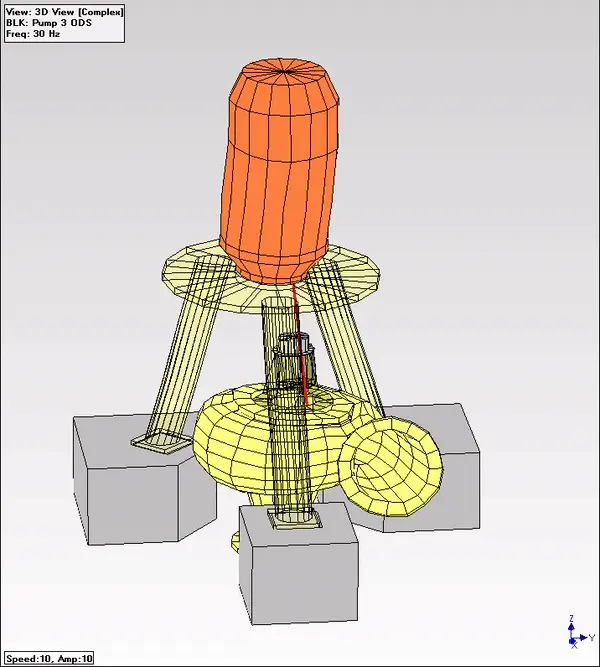

- Findings: The elevated synchronous vibration measured at the top of the bearing tower on both pumps was exceeding the ANSI/HI 9.6.4 specification and due to system resonance issues excited by 1xN and vane passing frequency. The modes going into resonance included the lateral pendulum mode of the pump rotor, the second bending mode of the motor/motor support, and the motor cantilever mode.

- Impact: MSI’s data concluded that the repetitive failure of the seals and pump bearings of the new pumps were not caused by “skewed flow distribution” that was claimed to be occurring at the non-reducing elbow (indicated by other consultants). The lack of a non-reducing elbow was not the cause of the vibration seen in the new pumps and was not causing the pump to operate less effective when compared with the pre-existing pumps. The resonance discovered was the reason behind the pump OEM recommending to lock out some of the speeds. MSI’s data suggested the pump OEM take these inherent structural resonances into account as a part of the design of the pump.

FRF plots from accelerometer at the top of the motor.

Vibration trend plot at the top of the bearing tower.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

New Orleans Flood Control Pumping Stations Vibration Analysis

MSI was recommended to analyze flood control pumping station system dynamics, including evaluation of the platform design with regard to vibration.

Case Study

Water Treatment Plant Pumps Fail Vibration Specification During Commissioning

A contractor putting together a water treatment facility encountered vibration issues with various pumps during commissioning.

Case Study

Newly Installed Water Treatment Plant Pumps Cavitating & Vibrating

A county water treatment plant heard “cavitation-like noise” from their newly installed pumps and called MSI for help.