Super-Synchronous Vibration in a Single Stage Overhung Centrifugal Pump

A pump manufacturer needed help identifying a super-synchronous vibration issue of a unit on the test stand. The manufacturer was trying to understand why the pump system was experiencing varying vibration levels at four different test locations.

- Problem Statement (Challenge)

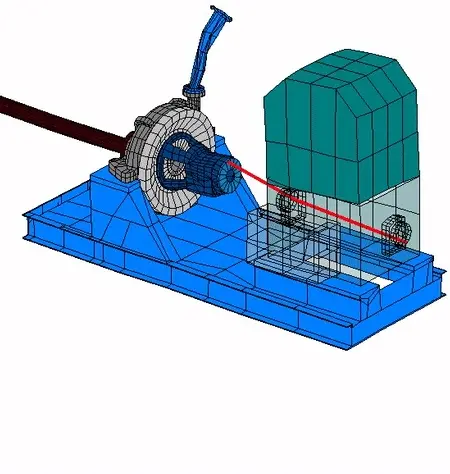

- What (type of machine): Overhung Single Stage Centrifugal Pump

- Where (State/ Country): New York

- Why (problem/reason): A pump manufacturer needed help identifying a super-synchronous vibration issue of a unit on the test stand. The manufacturer was trying to understand why the pump system was experiencing varying vibration levels at four different test locations.

- Work Performed

- Results/ Solution

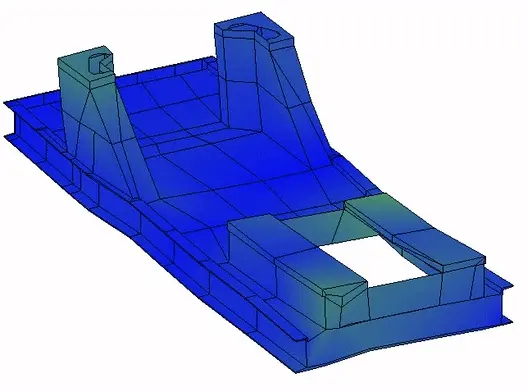

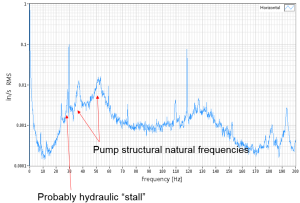

- Findings: The pump system exceeded the API vibration specification due to a combination of reasons. Excessive flexibility of the baseplate was shown in the ODS animations. A lightly damped shaft torsional natural frequency was found near the operating speed as well as a critically damped shaft lateral natural frequency. The pump casing had an axial/vertical rocking mode near the operating speed. Lastly, the pump was experiencing hydraulic instability at the diffuser and cavitation issues.

- Impact: The findings suggested that the current test setup for the unit had to be modified.The entire baseplate was recommend to be fully anchored to the floor to more closely resemble the permanently installed condition. It was suggested to conduct a fatigue analysis of the shafting system under the observed high torque oscillation.

Accelerometer FFT plot

Accelerometer FFT plot Read About :The Value Of Operating Deflection Shape –(ODS) Testing

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.