Dynamic Analysis Of A Street Sweeper For The Manufacturer

To identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer. The results showed locations where increased stiffness would extend bearing life.

- Problem Statement (Challenge)

- What (type of machine): Street Sweeper

- Where (State/ Country): Illinois

- Why (problem/reason): Identify modes that could cause premature bearing failures

- Work Performed

- Results/ Solution

- Findings: Mode was identified within 15% of 2x engine running speed, represented a significant risk of resonance condition that could result in vibration related bearing reliability issues.

- Impact: Addition of cladding was recommended to increase the separation margins from the operating speed to values greater than 15%. The proposed modifications provide a practical level of protection relative to vibration related bearing reliability issues.

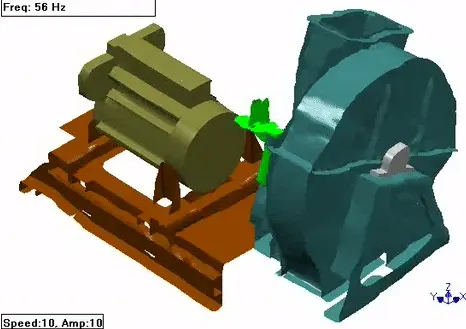

ODS model created in MEscope.

Animation.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.