Closed Cooling Water Glycol Pump Skid Flow & Vibration Issues

Pump Vibration Issues: The construction company of a natural gas powered electric generating facility was trying to understand why they were measuring a significant flow difference between field and factory test pump curves on the closed cooling water pump skid. MSI was contracted to diagnose the flow difference and perform a vibration inspection.

-

- What (type of machine): Natural Gas Powered Electric Generating Facility Overhung Bottom Suction Centrifugal Cooling Water Glycol Pumps

- Where (State/ Country): New Jersey

- Why (problem/reason): The construction company was trying to understand why they were measuring a significant flow difference between field and factory test pump curves on the closed cooling water pump skid.

- Work Performed

- Methods: Experimental Modal Analysis (EMA), Condition Monitoring, Operating Deflection Shape (ODS), Flow Traverse Pressure Readings

- Results/ Solution

- Findings: The flow differential was attributed to the ultrasonic flowmeter’s inability to detect the amount of air in the fluid, which affects the reading. The plant conducted their own air entrainment test which indicated a large amount of air was present in the fluid. The flow traverse test revealed that the flow profile entering the pump was skewed from top to bottom, which was not addressed by the existing flow straightener. Initial vibration readings indicated the pump vibrations were above allowable limits. Cavitation levels measured were considered damaging. Lastly, there was a pump bearing housing structural natural frequency within the operating speed range that was causing the high vibrations.

- Impact: The findings suggested that modifications need to be implemented on the pump bearing tower to shift a natural frequency out of the running speed excitation range. The suction piping design needed to be modified in order to eliminate the skewed velocity profile contributing to the cavitation. A Computational Fluid Dynamic Analysis (CFD) calibrated to the data collected on site to develop a solution to the flow problem with a greater chance of success upon implementation was recommended to the customer. The suggested modifications should help eliminate unscheduled outages to replace pump bearings and/or pump impellers.

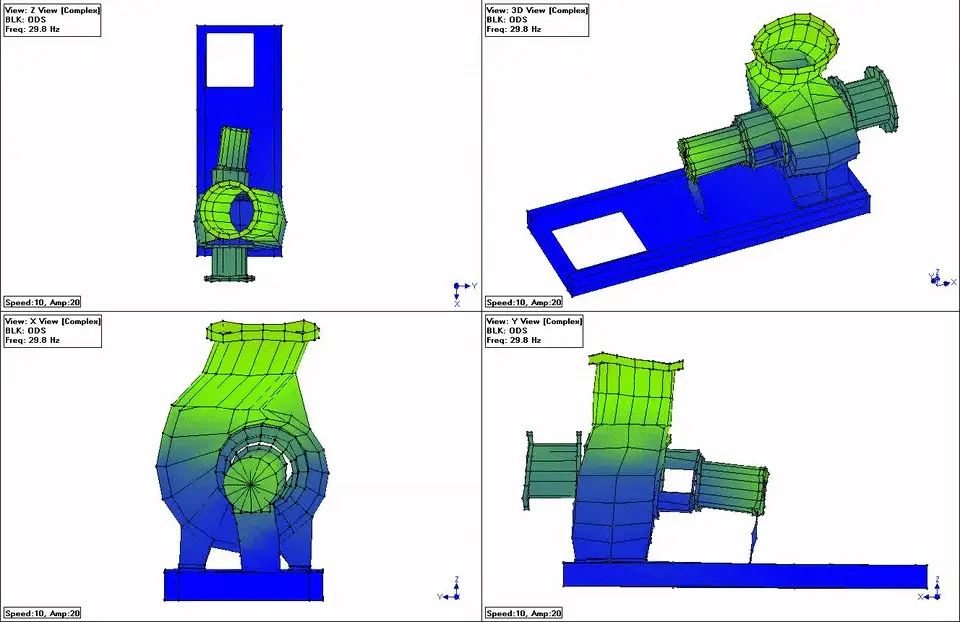

Animation.

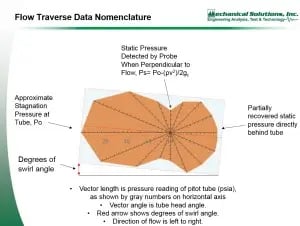

Explanation of flow traverse results.

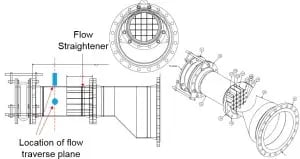

Image of current system flow straightener.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.