Ultra-Low Head Hydro Turbine Design Optimization

The customer approached MSI during the design phase of their project looking for assistance with improving an existing hydro turbine design for ultra-low head hydropower applications. The design incorporated unique elements not common in the industry, and presented several unique challenges.

Using MSI’s Hydro Turbine Design Process, areas for improvement were quickly and clearly identified. After discussing these with the customer, MSI focused on improving the blade design through the use of several design and analysis tools such as finite element analysis (FEA) and computational fluid dynamics (CFD). After rapid iteration, a revised blade design and subsequent operating profile provided an efficiency gain of several percentage points, providing the customer with a hydro turbine design capable of producing power effectively in ultra-low head installations.

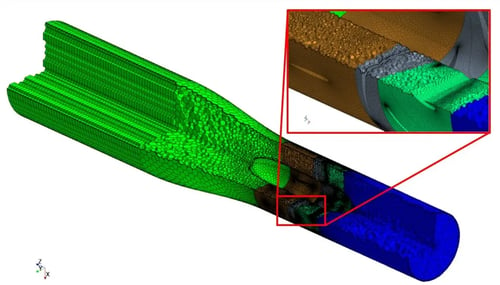

MSI's extensive CFD models (in this case over 16 million vertices) provide for accurate simulations and rapid iterations for design optimization.

CFD streamline analysis demonstrates optimized flow

CFD pressure analysis demonstrates an optimized pressure profile for low cavitation even at low heads

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.