Cavitation Assessment on Large Double-Suction Pumps

Challenge: Apply a new non-intrusive troubleshooting and test method for quantifying the amount of damage caused by pump cavitation.

Results: Impeller modification and impeller/wear ring material change.

Impact: Increased impeller operating life from less than two years to 15 years for four duplicate pumps, saving $840K in repair costs.

An OEM and an End User recently installed large double suction pumps and determined that the pumps were a suspected noise source. The pump station owner needed to prove that the noise was a result of cavitation and to assess the potential for cavitation to significantly reduce pump life. Of particular concern was a periodic chugging sound, which was present when the largest pumps were operating within a flow range of approximately 100% to 130% of BEP.

Mechanical Solutions, Inc. (MSI) has developed a high-frequency accelerometer technique for quantifying the amount of damage occurring in a cavitating pump. This new method can quickly diagnose cavitation in pumps, valves, and other fluid system components. Additionally, MSI can estimate the severity of the cavitation damage, determine if component modifications are essential (for meeting reliability), and determine if the cavitation noise is simply a nuisance.

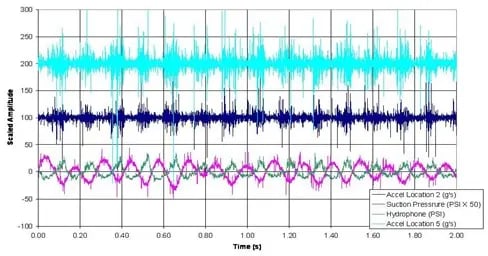

Plot showing the periodic acceleration, suction sound pressure, and suction pressure measured while the pump was operating in a condition of cavitation surge.

MSI has found that a reliable indicator of potential pump cavitation damage is the instantaneous casing acceleration during pump operation under suspected cavitation conditions. This technique measures the high frequency (short time period) spikes in the vibration time signal, which result from individual cavitation bubbles collapsing on the internal surfaces of the pump. Since the vibration spikes are considerably higher in amplitude when the bubbles collapse on a surface as opposed to collapsing in the free stream, a quantitative assessment of the potential for cavitation damage to the pump can be made. By measuring the instantaneous acceleration spikes, MSI can directly measure the pump’s material response to the cavitation events. Measuring the sound frequency spectrum, as others have done, provides a less direct measurement since the effects must be transmitted from the pump casing to the air before being measured, and provides ambiguous tell-tales. Even difficult‐to‐perform dynamic pressure or hydrophone measurements are less direct because they provide no information about whether cavitation bubbles are harming the metal.

MSI performed tests, which consisted of measuring the pressure pulsations in the suction pipe, sound pressure near the impeller inlet, instantaneous casing acceleration at many surface locations, and sound pressure in the air surrounding the pumps. Past experience indicated levels of peak instantaneous acceleration levels indicative of damaging cavitation, versus levels below which no damage from cavitation would occur. In this case, peak acceleration levels on the pumps were measured as high as four times that which would be indicative of sufficient cavitation to erode the impeller and/or casing. Further post‐test inspection of the internal pump revealed cavitation erosion damage to the impeller vane, shroud surfaces, and the nearby casing surface. In a similar pump investigation using MSI’s technique, MSI determined that after 1000 operating hours at 3 times the acceleration limit, the 3/4 inch 316L impeller vanes had lost half their thickness.

Comparing the various measurement methods shows a good correlation between suction pressure measurements, suction sound pressure measurements (hydrophone), and instantaneous acceleration (image above). The measurement that provided the most ambiguous data was the more typically performed airborne sound pressure measurement. Discussions with the pump OEM revealed the pump suction had been ‘oversized’ to meet the stringent NPSH requirements at the minimum suction head condition. The result was a pump that experienced suction re-circulation at flow rates above BEP flow rate (typical re-circulation cavitation damage occurs below BEP). The problem was compounded since the re-circulation set up an unsteady flow pattern in the pump suction, resulting in a cavitation surge, not only damaging the impeller but also shaking the entire pump system. In order to minimize this cavitation surge or “chugging” effect, the impeller design was modified.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.