Replacing A Pressure Reducing Valve With A Hydro Turbine For A Municipal Water Supply

A municipality receiving its water supply from a high elevation spring sought to replace an energy wasting pressure reducing valve with a hydro turbine. MSI was tasked with designing the turbine to capture power over a challenging range of operating conditions.

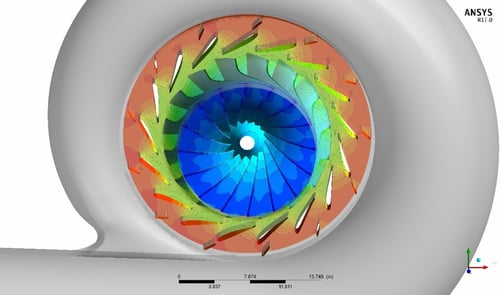

A Francis style hydro turbine was chosen as a design normally well-suited for varying flows, but generally less effective with variations in head pressure. The challenge was to come up with a single turbine capable of high efficiency for both current and future head conditions.

MSI's custom-designed Francis style hydro turbine predicted excellent performance over a wide range of operating conditions

MSI's custom-designed Francis style hydro turbine predicted excellent performance over a wide range of operating conditions

After extensive iterative design and analysis consisting of finite element analysis (FEA) and computational fluid dynamics (CFD), MSI developed a runner with high efficiency across the operating range of head and flow pressures. Cavitation was also a concern, given the wide operating range. The model predicted cavitation would not be a problem, and the turbine performed as expected.

The runner performed as expected with high efficiency and without cavitation

The runner performed as expected with high efficiency and without cavitation

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.