Troubleshooting The Kringle 3000 And Saving Christmas

After a high profile catastrophic failure, the North Pole Operations Team needed to fix their auxiliary thrust system once and for all

Mechanical Solutions, Inc. is often called upon to resolve some of the most challenging rotating machinery problems in the world, saving significant amounts of money in lost production costs and trial-and-error fixes. This particular client, however, had a very unique need – saving Christmas.

MSI was contacted by the North Pole Operations Team after a catastrophic field failure of the auxiliary thrust system for their primary package distribution platform, Santa’s Sleigh. The original Santa’s Sleigh had been powered solely by belief in Santa Claus. However, belief in Santa (as measured by the onboard Clausometer) had shown decreasing belief level trends over time, such that an auxiliary thrust system was required to meet distribution objectives. The Kringle 3000 500-Reindeer power turbine was selected for its quick start capabilities and flexible operations profile, and had been performing quite well for the past several Christmas seasons.

The Kringle 3000 auxiliary turbine is designed to supplement thrust power when belief in Santa levels are too low to fly Santa's Sleigh

Santa's Sleigh package delivery system, including the 500-Reindeer power Kringle 3000 auxiliary turbine

|

"MSI was able to quickly diagnose a problem of increasing severity, threatening operations of one of the most important enterprises there is. We appreciated their responsiveness and ability to provide a lasting solution. We have permanently placed them on the Nice List." - Papa Elf, Director of Operations, North Pole |

On the Christmas Eve of the failure, the Clausometer fell to historic low levels and the Kringle 3000 turbine was driven to previously unseen power levels to compensate. Shortly thereafter, the Kringle 3000 broke loose from Santa’s Sleigh, requiring grounding of the platform. The turbine was reattached in the field, and operations resumed. However, the resultant power was insufficient to avoid an obstacle during takeoff, and the Kringle 3000 broke loose a second time. Fortunately, during this publicly witnessed second failure event, the Clausometer levels subsequently spiked to maintain operations as scheduled without the auxiliary thrust system.

Given the continuously fluctuating Clausometer levels, the North Pole Operations Team wanted to understand the root cause of the Kringle 3000 failure, and get a fix implemented to ensure ongoing operations, even with diminishing belief in Santa.

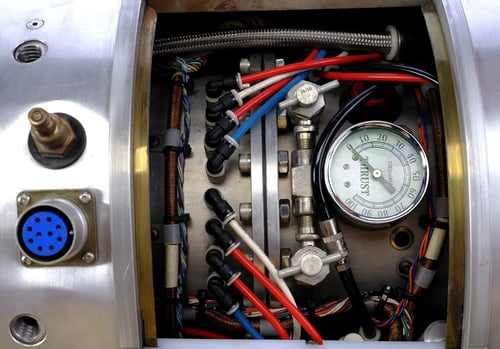

Local control panel on the Kringle 3000 auxiliary turbine, indicating zero thrust levels during flameout conditions due to resonance

After specialized testing of Santa’s Sleigh under varying belief conditions, MSI observed increased vibration levels on the Kringle 3000, up to 0.76 in/s RMS. The frequency of the vibration correlated with the bending mode structural natural frequency of the turbine, and would produce a flame-out condition during resonance. Previously this had not been an issue due to the lower auxiliary thrust power required, but now was in a near constant state of resonance with higher power levels. Upon recommendation from the North Pole Operations Team technical staff, maple syrup was tried as an alternative fuel source to attempt to alter the thrust loads and detune the resonance. This proved ineffective (and messy). A thorough Root Cause Analysis was performed, and it was concluded that no permanent damage was sustained to the auxiliary turbine during the field failures. It was acceptable to reattach the unit in the field (as the client had done), and it would continue to function properly with appropriate modifications. Finite Element Analysis (FEA) was then conducted to model the observed conditions (assuming standard aviation turbine fuel, not maple syrup), and to implement a hypothetical fix.

Finite Element Analysis (FEA) confirmed a bending mode structural natural frequency at operating conditions

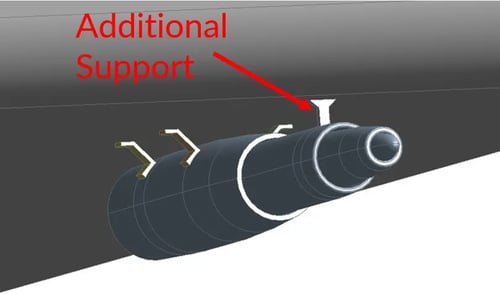

FEA did indeed confirm that there was a bending mode structural natural frequency overlapping with running speed, creating a destructive resonance condition. An additional aft strut was modeled to stiffen the turbine support structure and detune the resonance condition more than 15% away from the operating speed range. The North Pole Operations Team fabricated the additional strut, and the Kringle 3000 was retested with vibration levels falling to less than 0.1 in/s RMS, even under extremely low belief in Santa conditions.

MSI recommended an additional support on the aft end of the turbine, which shifted the natural frequency more than 15% away from the operating speed

While MSI managed to address the resonance condition and anticipates excellent performance this Christmas, the underlying root cause of the failure condition still exists - declining Christmas spirit. It is our ongoing recommendation that, "The best way to spread Christmas cheer is singing loud for all to hear," preferably without resonance. Merry Christmas to all!

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Solids Handling Pump Repetitive Failure of Bearing and Seal

An engineering construction firm needed help in determining the root cause for the repetitive pump bearing and seal failures of a solids handling pump and to provide a solution to eliminate the issue.

Case Study

Design Assessment Mitigates Risk

A design assessment was carried out in an effort to prevent potential premature bladed disk and impeller fatigue failures of three newly installed critical compressor trains.

Case Study

Development of a Prototype Vacuum Blower

A major aerospace equipment supplier/manufacturer needed to design and prototype an FAA-approved vacuum generator for use on commercial aircraft.