Seismic Analysis

Enhancing Nuclear Power Plant Pump System Reliability

“How can nuclear power plants ensure their rotating machinery systems including Vertical Turbine Pumps (VTPs) can withstand earthquakes without compromising safety or performance?”

Seismic analysis of rotating machinery systems including VTPs is critical for protecting plant infrastructure and maintaining reliable operation during seismic events. MSI regularly performs seismic analysis to address this challenge utilizing detailed three-dimensional Finite Element Analysis (FEA) methods. This case history provides an example focused on a 500 hp service water VTPs. The specified risk reduction assessment verified structural integrity, bearing loads, and stress levels under site-specific earthquake loading, confirmed compliance with nuclear seismic qualification requirements, and identified design improvements to avoid high vibration due to resonance.

Not all seismic analyses are created equal. Specifications for seismic analysis requirements need to be carefully worded as such an analysis can range from a very simplified approach up to a more challenging transient analysis. This blog provides more detail about the Response Spectrum Analysis (RSA) method.

Project Background: Seismic Qualification for Nuclear Pumps

A nuclear power company purchased several new service water vertical turbine pumps. As required for all new nuclear installations, the VTP systems had to demonstrate the ability to withstand earthquake loading without structural failure or loss of function. Therefore, the pump manufacturer commissioned MSI to perform a comprehensive seismic qualification analysis.

Finite Element Analysis Approach

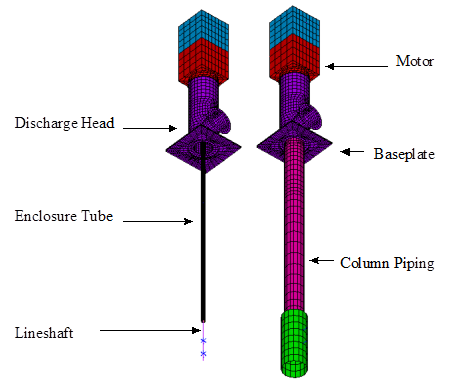

MSI engineers developed a detailed three-dimensional finite element analysis (FEA) model of each pump system. The model included all major system structural, as well pump-specific structural and rotating components to accurately capture dynamic behavior under seismic excitation.

Components Included in the Model

• Nearby foundation

• Baseplate

• Discharge piping to the first support

• Discharge head

• Column shaft

• Caisson

• Motor casing and motor rotor

• Lineshaft

• Enclosure tube and spiders

Finite element model of the vertical turbine pump.

Additional Modeling Considerations

• Mass and inertia of impellers and rotating elements

• Lineshaft bearings, motor bearings, and enclosure tube spiders with representative stiffness values

• Effective added mass of surrounding water

• Stiffening effects of thrust load and enclosure tube pretension

This high-fidelity model ensured accurate prediction of natural frequencies, stresses, and bearing loads during seismic events.

Natural Frequency and Resonance Evaluation

The first phase of the analysis focused on identifying natural frequencies and comparing them to:

• Frequencies with high seismic input energy

• Multiples of the pump running speed (1×, 2×, etc.)

Key Findings

• No natural frequencies were found near the dominant seismic excitation frequency (~5 Hz)

• First below-ground reed frequencies were below the primary seismic range

• All other modes, including first above-ground modes, were above the seismic range

• Some lateral bending modes occurred near low multiples of running speed, indicating a potential resonance risk during normal operation

These findings prompted design modification recommendations to avoid potentially serious operational vibration issues due to resonance near the pump running speed.

Seismic Response Spectrum Analysis

Following the modal analysis, MSI performed a seismic Response Spectrum Analysis (RSA) using site-specific seismic response spectra.

Analysis Method

• Seismic inputs applied simultaneously through the pedestal foundation

• Response spectrum method used to capture maximum dynamic response

• Stress, displacement, and bearing load responses evaluated

Seismic Response Results

• Maximum seismic response was dominated by the first below-ground mode

• Flexure of below-ground piping produced peak stresses at ground-level connection points

• Calculated stresses and bearing loads remained within acceptable design limits

Results and Engineering Outcomes

MSI successfully demonstrated that the vertical turbine pumps could:

• Withstand the specified earthquake loading

• Maintain structural integrity and acceptable bearing loads

• Meet nuclear seismic qualification requirements

In addition, MSI provided engineering recommendations to shift lateral lineshaft natural frequencies away from operating speed harmonics, helping prevent resonance-related vibration problems during normal pump operation. The analysis was completed within an aggressive project schedule, supporting timely plant installation and commissioning.

Why Seismic Analysis Matters for Rotating Machinery Systems including pumps

• Ensures nuclear safety and regulatory compliance

• Identifies resonance risks before installation

• Prevents long-term vibration and fatigue failures impacting plant availability and maintenance budgets

• Protects bearings, shafts, and structural connections

• Supports reliable operation during and after seismic events

Frequently Asked Questions (FAQ)

Why is seismic analysis required for vertical turbine pumps in nuclear power plants?

Seismic analysis is required to demonstrate that vertical turbine pumps can withstand earthquake loading without structural failure or loss of function. Nuclear regulations mandate seismic qualification to ensure safety, protect critical systems, and maintain operability during and after seismic events.

What type of seismic analysis was performed for these pumps?

A three-dimensional finite element analysis (FEA) was performed, followed by a seismic Response Spectrum Analysis (RSA). Site-specific seismic response spectra were applied simultaneously through the pump pedestal foundation to evaluate stresses, displacements, and bearing loads.

Which pump components were included in the analysis model?

The finite element model included the pump system including the nearby foundation, baseplate

discharge piping to the first support, discharge head, column shaft, caisson, motor casing, motor rotor, lineshaft, enclosure tube, enclosure tube spiders, impellers, and bearings. The added mass of surrounding water and the stiffening effects of thrust load and enclosure tube pretension were also included.

How were natural frequencies evaluated during the study?

Natural frequencies were calculated and compared to both dominant seismic excitation frequencies and multiples of the pump operating speed. This ensured that no critical resonance conditions would occur during earthquake loading or normal pump operation.

What seismic response mode dominated the pump behavior?

The maximum seismic response was dominated by the first below-ground mode. As the below-ground piping flexed during seismic excitation, peak stresses occurred at the ground-level connection points.

Were the calculated stresses and bearing loads acceptable?

Yes. The analysis demonstrated that all stresses and bearing loads remained within acceptable design limits for the specified site-specific seismic loading conditions.

Why is resonance with pump running speed a concern?

Resonance near multiples of the pump running speed can cause excessive vibration, increased bearing loads, fatigue damage, and reduced reliability. Identifying and mitigating these resonances is critical for safe and reliable long-term pump operation.

What additional benefits resulted from the seismic analysis?

In addition to verifying seismic qualification, the analysis identified lateral lineshaft bending modes near operating speed harmonics. Design modifications were recommended to shift these frequencies away from running speed, preventing potential vibration problems during normal operation.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.