Oil Tanker Pumping Station Vibration Testing and Troubleshooting

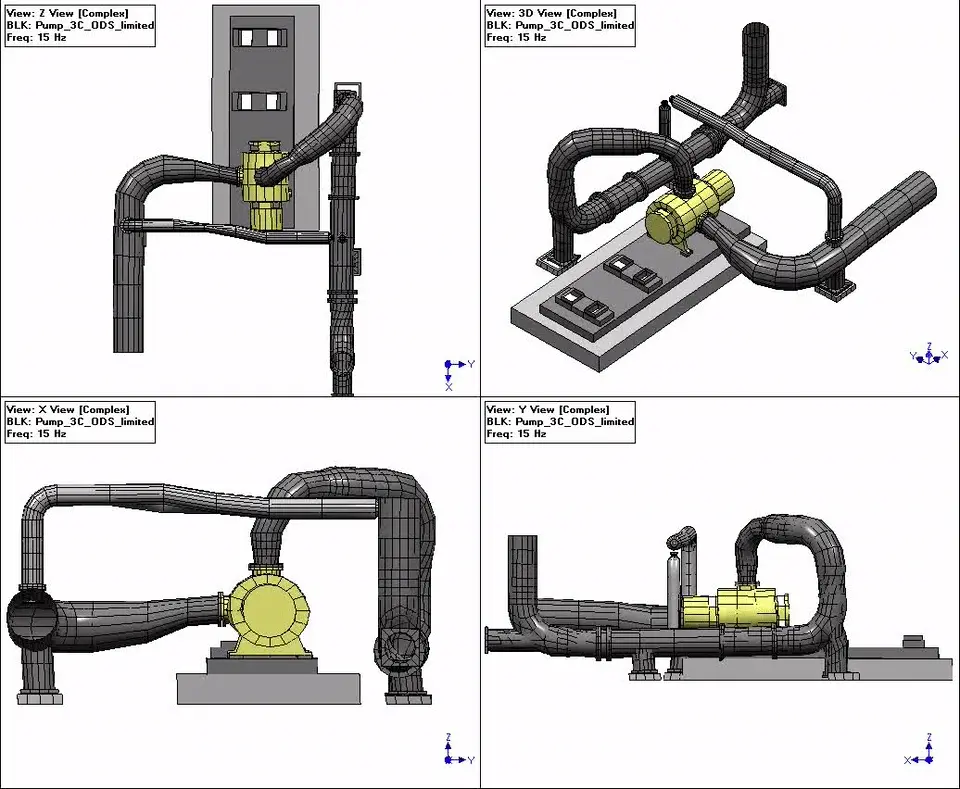

Oil Tanker Vibration Testing: Troubleshooting and performing pump vibration testing on a new oil tanker pumping station in Colombia consisting of 4 screw pumps. Specialized testing revealed that piping natural frequencies were to blame.

- Problem Statement (Challenge)

- What (type of machine): Oil Tanker Pumping Station Screw Pump

- Where (State/ Country): Colombia

- Why (problem/reason): Identify reason(s) for high vibration causing damage to a new oil pumping station installation made up of four screw pumps.

- Work Performed

- Results/ Solution

- Findings: A group of modes was identified within 15% of the 1xN, 2xN, and 4xN (lobe passing frequency) pump running speed, representing resonance conditions that could result in vibration-related reliability issues occurring.

- Impact: Finite Element results indicated that adding piping supports at strategic locations would result in separation margins greater than 15% separation. The proposed modification provided a practical level of protection relative to vibration-related reliability issues due to a resonance condition.

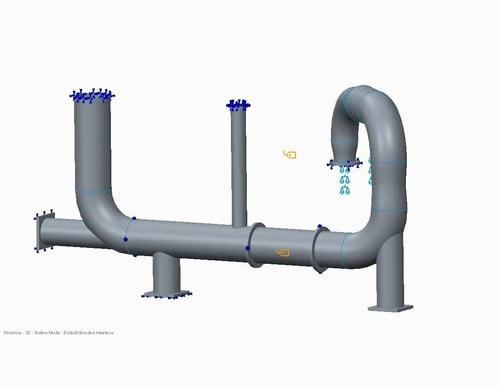

ProE model with constraints.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Troubleshooting a Pipeline Renewable Diesel Screw Pump

Elevated vibration levels were causing a pipeline company screw pump problems.

Case Study

Petrochemical Ammonia Recip Compressor Piping Troubleshooting

Excessive motion by the discharge piping of a petrochemical ammonia reciprocating compressor startled the operators.

Case Study

Oil Tanker Pumping Station Screw Pump Troubleshooting

Troubleshooting a new oil tanker pumping station in Colombia consisting of 4 screw pumps. Specialized testing revealed that piping natural frequencies were to blame.