Assess Foundation Effects on Existing Solids Handling Pumps

Pump Engineers Need To Accurately Predict Structural Natural Frequencies Of A Pump System By Including The Foundation

The Civil Engineers at a major Architect/Engineering firm used MSI’s pump engineering experience and modern methodology to determine the effect of the station foundation on the structural natural frequencies of a dry-pit non-clog vertical pump which was due for replacement. Pump OEMs will understandably limit their own analysis efforts to the scope of their supply, and may not include piping effects and/or will assume the floor is infinitely stiff (it isn't). While leaving out system effects may be fine for a rotordynamics analysis, it makes a structural analysis misleading at best. The goal of a properly performed structural design assessment is to ensure that the pump and associated components will not vibrate based on how the pump, motor, and associated system elements will be installed and behave in the system at various performance conditions.

In this case, by determining the effect of the foundation on the natural frequencies of the currently installed pumps, the importance of including the flooring/foundation in future finite element analysis (FEA) analysis predictions for the new pumps could be quantified. The Architect/Engineering firm could then be sure to state in their specification that the station foundation should be modeled explicitly in any future FEA calculations.

Based on MSI engineers' FEA models of the full pump assembly, including the station foundation modeled in full 3D, it was predicted that the flexibility of the flooring/foundation could influence the 1st bending “global rocking” modes up to 17.6% and the 2nd bending “C-shaped” modes up to 32.1%. For this reason, MSI pump engineers highly recommended that the Architect/Engineering firm include language in their specification that a detailed model of the station foundation should be included in any structural natural frequency calculations of the future pump system.

The following table is a comparison of baseline modes and “infinitely stiff floor” modes of a dry-pit non-clog vertical pump assembly in order to evaluate the effects of the flooring/foundation.

| Dry-Pit Non-Clog Vertical Pump Structural Modes: Assessment of Foundation Effects | |||||

| Pump Speed (RPM): 1070-1170 | |||||

| Description | Baseline FEA Predicted Natural Frequency | Natural Frequency with Infinitely Stiff Floor | Percent Influence of Foundation | ||

| Hz | CPM | Hz | CPM | % | |

| 1st Bending "Global Rocking" Mode Perpendicular | 16.9 | 1,014 | 20.5 | 1,230 | 17.6 |

| 1st Bending "Global Rocking" Mode Parallel | 18.4 | 1,104 | 19.3 | 1,158 | 4.66 |

| 2nd Bending "C-Shaped" Mode Perpendicular | 29.4 | 1,764 | 43.3 | 2,598 | 32.1 |

| 2nd Bending "C-Shaped" Mode Parallel | 30.8 | 1,848 | 38.3 | 2,298 | 19.6 |

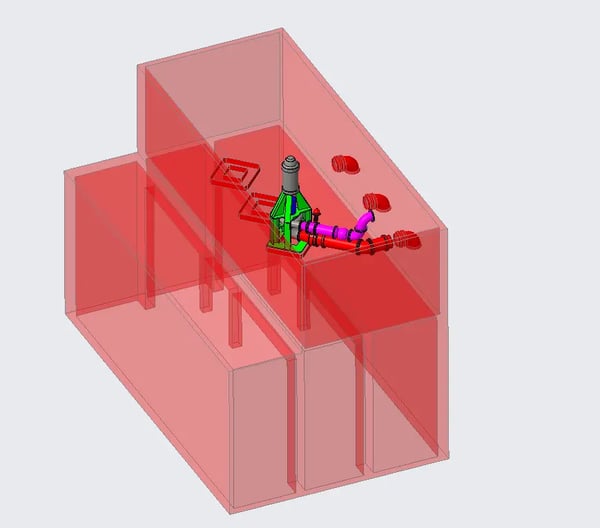

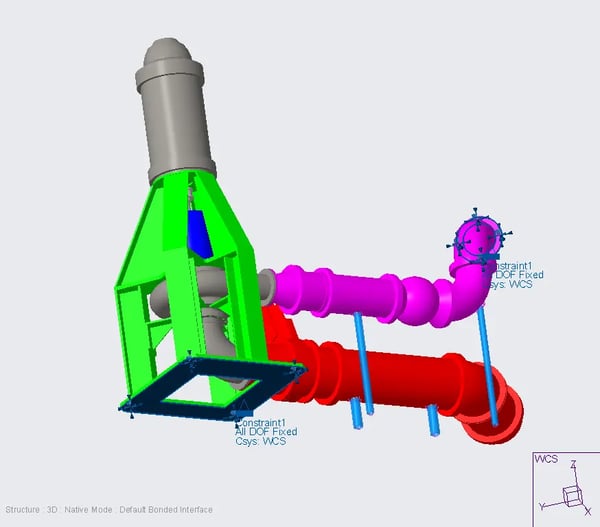

The following image is a Creo 4.0 solid model of the dry-pit non-clog vertical pump assembly used to match the structural natural frequencies measured by MSI field engineers. It should be noted that to obtain a good match with the field measured structural natural frequencies, it was necessary to include the full station foundation flooring.

For comparison purposes, what follows is a Creo 4.0 solid model of the dry-pit non-clog vertical pump assembly used to assess the effects of the station flooring/foundation on the pump structural natural frequencies. It should be noted that these boundary conditions are utilized only for comparison purposes, and that the correct configuration when performing a pump system structural natural frequency analysis is shown in the first image with a complete model of the surrounding system, including the foundation.

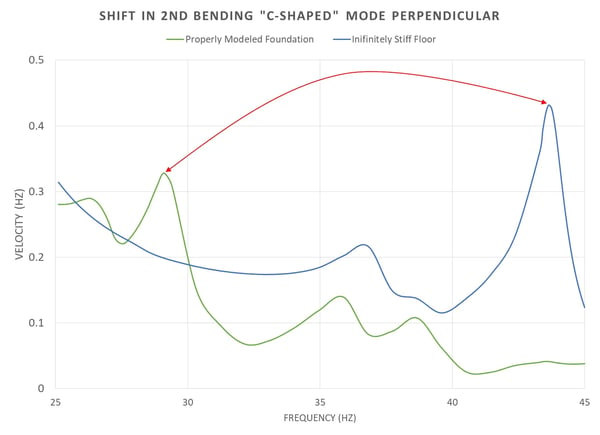

Let's take a more detailed look at the 2nd Bending "C-Shaped" Mode, where the shift in natural frequency was significant. The following animation compares the model of the 43 Hz forced response of the infinitely stiff floor (i.e, no foundation) with the correctly modeled system, including the foundation.

2nd Bending "C-Shaped" Mode response at 43 Hz with infinitely stiff floor

2nd Bending "C-Shaped" Mode response at 43 Hz with infinitely stiff floor

Forced response at 43 Hz for model including foundation showing minimal response

The following chart demonstrates the shift in the 2nd bending mode from 43 Hz to 29 Hz with a properly modeled system, including the foundation.

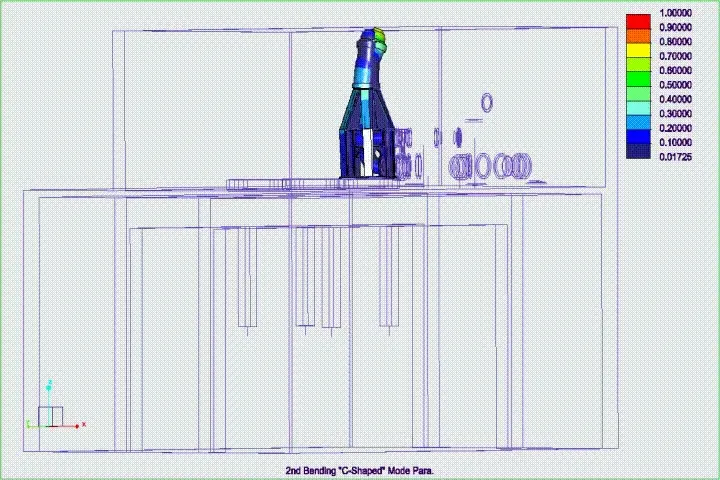

Finally, the properly modeled forced response at 29.4 Hz is shown, which was not evident using the infinitely stiff floor assumption.

2nd Bending "C-Shaped" Mode response at 29 Hz with foundation included

2nd Bending "C-Shaped" Mode response at 29 Hz with foundation included

Check out these related case studies to see how the suction/discharge piping and water level affect your pre-installation design assessment as well.

If you would like to discuss pre-installation design assessment for your pump or other rotating machinery project with an experienced MSI Engineer, contact us.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

New Orleans Flood Control Pumping Stations Vibration Analysis

MSI was recommended to analyze flood control pumping station system dynamics, including evaluation of the platform design with regard to vibration.

Case Study

Water Treatment Plant Pumps Fail Vibration Specification During Commissioning

A contractor putting together a water treatment facility encountered vibration issues with various pumps during commissioning.

Case Study

Newly Installed Water Treatment Plant Pumps Cavitating & Vibrating

A county water treatment plant heard “cavitation-like noise” from their newly installed pumps and called MSI for help.