Aeroderivative Gas Turbine Natural Frequency Excited By Imbalance

MSI conducted vibration testing of an aeroderivative gas turbine on the west coast of the United States. The unit had been reported to have high vibration levels (2 in/s peak) at the HP compressor speed at maximum operational load (45MW).

MSI conducted vibration testing of an aeroderivative gas turbine on the west coast of the United States. The unit had been reported to have high vibration levels (2 in/s peak) at the HP compressor speed at maximum operational load (45MW).

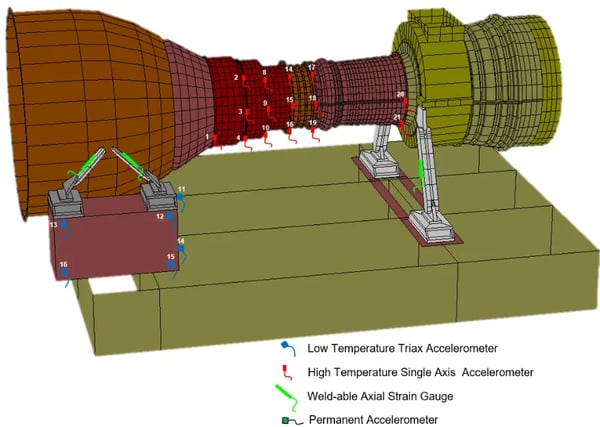

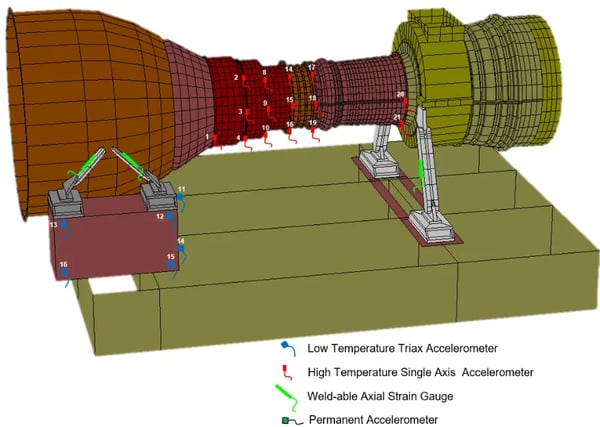

Continuous Monitoring: Vibration and Strain Gauge Locations

MSI performed specialized vibration testing that included experimental modal analysis (EMA), continuous monitoring using strain gauges, and operating deflection shape (ODS) characterization. This testing indicated that the high vibration was due to its elevated residual imbalance and some amplification due to a structural natural frequency near running speed. It was recommended to increase the pre-load of two legs and one support and to perform balancing using the U=1W/N approach, where U is the residual imbalance (oz-in) for the entire rotor, W is the weight of the rotor (lbm) and N is the operating speed.

- Work Performed

- Results/ Solution

- High vibration due to elevated residual imbalance and some amplification due to a structural natural frequency near running speed

- Impact: Increasing the pre-load of the forward left and right legs and the aft right support & recommended to perform this balancing using U=1W/N approach, where U is the residual imbalance (oz-in) for the entire rotor, W is the weight of the rotor (lbm) and N is the operating speed.

172 Hz Mode Shape (HP Compressor Bell Mode and Aft Left Support Bending)

Instrumentation used during the continuous monitoring testing (one side)

Instrumentation used during the continuous monitoring testing (one side)

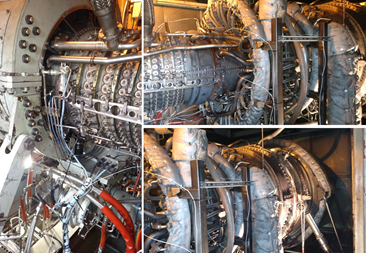

Various angles of machine investigated

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Solids Handling Pump Repetitive Failure of Bearing and Seal

An engineering construction firm needed help in determining the root cause for the repetitive pump bearing and seal failures of a solids handling pump and to provide a solution to eliminate the issue.

Case Study

Design Assessment Mitigates Risk

A design assessment was carried out in an effort to prevent potential premature bladed disk and impeller fatigue failures of three newly installed critical compressor trains.

Case Study

Development of a Prototype Vacuum Blower

A major aerospace equipment supplier/manufacturer needed to design and prototype an FAA-approved vacuum generator for use on commercial aircraft.