Premature Bearing Failures In Nuclear Bus Duct Cooling Fans

A nuclear power plant had changed bus duct cooling fan bearings approximately five times in two years. The plant wanted to find the root cause of the repetitive bearing failure so they could address the main problem instead of changing out bearings more frequently. The increased replacement frequency brought increased cost and unscheduled maintenance.

- Problem Statement (Challenge)

- What (type of machine): Bus Duct Cooling Fan in Nuclear Service

- Where (State/ Country): Tennessee

- Why (problem/reason): A nuclear power plant had changed bus duct cooling fan bearings approximately five times in two years. The fan bearings were replaced due to detected fatigue failure, high harmonics of the running speed, and eventually the locking ring at the outboard bearing was discovered to be chipped/ cracked. The plant wanted to find the root cause of the failures so they could address the main problem instead of changing out bearings more frequently. The increased frequency brought increased cost and unscheduled maintenance.

- Work Performed: MSI's Troubleshooting Approach

- Results/ Solution

- Findings: The root cause of the high vibration and repetitive failure of the bearings was due to fatigue cracks present at the welds along the radial vanes and the inner can structure. The initial cracks were predicted to have initiated from unintended forces/impacts during the impeller extraction for bearing replacements. Cracks of the welding of the inner can were present at the lower section of the can where the “A” frame is supported (at 4 and 8 O’clock positions).

- Impact: The plant discovered the locations where cracks existed and fully repaired the welds. The plant was able to extend its maintenance schedule of the equipment and no longer has to worry about costly, unscheduled bearing replacements.

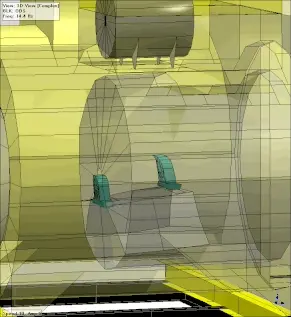

X-section view of the duct cooling fan

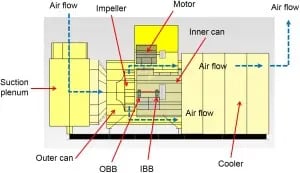

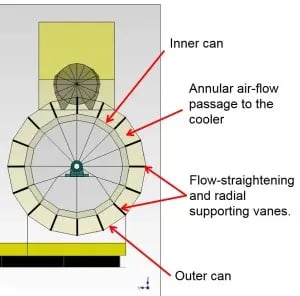

X-section view of the duct cooling fan Front view showing can and radial support vanes

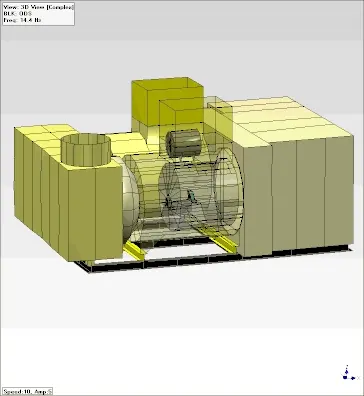

Front view showing can and radial support vanes  Picture of weld cracks found

Picture of weld cracks found

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.