Unique Testing For Pipe Resonance In A Nuclear Power Plant

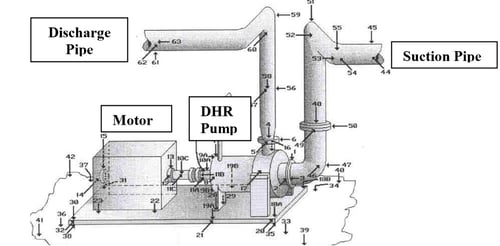

Bearings and seals were prematurely failing in a safety-related Decay Heat Removal Pump, which was a single-stage end-suction volute pump. MSI performed pump vibration testing and analysis to help understand the problem, before offering a solution. Specific pump testing included Operating Deflection Shape (ODS) testing and modal impact ("bump") testing using the MSI Time-Averaged Pulse (TAP™) procedure while the pump was operating.

The ODS vibration testing demonstrated that the direct reason for the reliability problems was that the pump casing was badly distorting dynamically, with a dominant frequency of the pump's impeller vane pass versus the casing’s single volute tongue. The motion of the system at this frequency involved a vertical “bouncing” of the oversize discharge pipe, which tended to “jam” the pump casing through the dynamic force it imparted to the pump discharge nozzle.

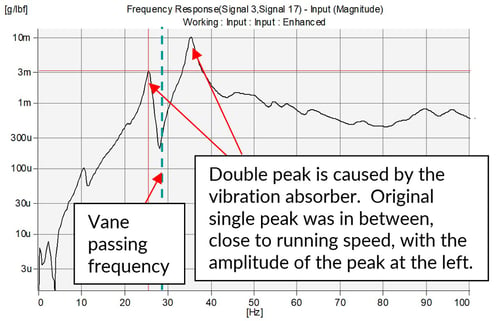

A TAP™ impulse modal test was performed on the pump and piping, and determined that a structural natural frequency dominated by vertical motion of the discharge pipe was nearly coincident with the first harmonic of the vane pass frequency, thereby causing a pipe resonance. This resonance was relatively poorly damped, based on the “half power” width of the resonant response peak of the Frequency Response Function for this mode, as obtained from the modal test.

Decay Heat Removal Pump and Multiple Test Points

Is That Really The Pump Problem?

|

"When distant from stiffening components such as flanges or piping supports, this technique allows the pressure pulsation (which makes the pipe radially expand) to be separated from the piping gross structural vibration..." |

The regulatory agency and plant needed to verify that the pipe resonance issue was the only reason for the increased vibration. If it was, then they would also need to determine how best to eliminate the excessive vibration response, and end the chronic failures. This was problematic, since there were no piping taps near the pump discharge to check the fluid dynamic pressure, and if the piping was violated by installing a tap, it would need to be re-qualified for system operation in a safety-related situation. The cost of this re-qualification would be high, and the plant might be required to shut down until analysis was completed. On the other hand, the plant might be required to shut down because of the DHR pump chronic failures, until there was quantitative assurance that the source of the failures had been successfully addressed.

MSI engineers applied a vibration testing technique that they had used successfully in other plants where pressure pulsation measurements were required in pump or compressor systems where many axial pressure readings were needed to evaluate acoustic natural frequency mode shapes, but where pressure taps were sparse and/ or unwelcome (e.g., in refinery piping). The special vibration testing method consists of using a minimum of 4 uniaxial accelerometers, attached perpendicular to the pipe wall at 90 degree intervals around the periphery of the pipe, and doing this at each location where pulsation readings are needed.

When distant from stiffening components such as flanges or piping supports, this technique allows the pressure pulsation (which makes the pipe radially expand) to be separated from the piping gross structural vibration, which merely translates the pipe as a relatively rigid body, unless shell modes are suspected. Shell modes occur at high frequencies (order of 1 kHz and higher, depending upon pipe thickness divided by diameter squared). MSI measured the pressure pulsation one pipe diameter downstream of the discharge nozzle, and then demonstrated with a finite element analysis (FEA), calibrated by the test results, that the pulsation level was indeed close to that required to drive the discharge piping resonant response at the vibration level that had been detected, verifying it as the “problem source”.

How To Fix Nuclear Pump Piping Resonance

MSI then used the confirmed FEA model of the pump and piping system together to perform some “what if” analyses of possible alternative solutions to the piping resonance problem. Options of adding mass to the pipe, use of a piping damper (shock absorber), stiffening of the pipe supports, and lengthening of the pipe were all explored, and found viable. However, each of these solutions would require piping re-qualification, which is a substantial undertaking for a nuclear power plant.

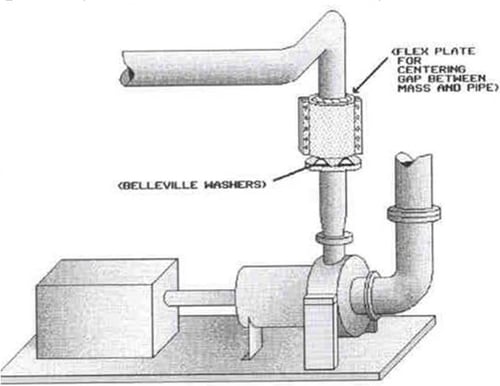

MSI then designed a low weight dynamic absorber, in the form of a low-mass, thin-walled pipe “clamshell” surrounding the discharge pipe vertical leg, able to move vertically separately from the discharge pipe, attached to the discharge pipe through clamping plates that had tuned and adjustable stiffness in the vertical direction. The assembly was shown analytically, and by test, to quench the resonance at the vane pass acoustic frequency. Because the assembly was of sufficiently low mass, and did not penetrate the discharge pipe, only the absorber needed analysis and review/ approval.

Design concept of tuned vibration absorber that did not require piping requalification

The net result was a 25x reduction in vibration amplitude at the vane pass frequency without major piping modification and requalification

The net result was a 25x reduction in vibration amplitude at the vane pass frequency without major piping modification and requalification

Check out the case studies below for additional examples of MSI's diagnosis of problems combined with effective, implementable solutions. If you would like to have us diagnose and solve your rotating machinery problem, Contact Us and we would love to help you.

MSI In Action

REAL-WORLD EXAMPLES AND CASE STUDIES

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.