Ammonia Recip Compressor Pipe Vibration Problem Solved

Positive Displacement Compressor: Excessive motion by the discharge piping of a petrochemical ammonia reciprocating compressor (positive displacement compressor) startled the operators. MSI was tasked with finding the root cause and suggesting a fix for this rotating machinery vibration issue.

- Problem Statement (Challenge)

- What (type of machine): Petrochemical Ammonia Reciprocating Compressor (Positive Displacement Compressor)

- Where (State/ Country): New Jersey

- Why (problem/reason): Operators started to notice large amounts of swaying in the discharge piping and wanted the problem investigated to prevent a potential ammonia leak.

- Work Performed

- Results/ Solution

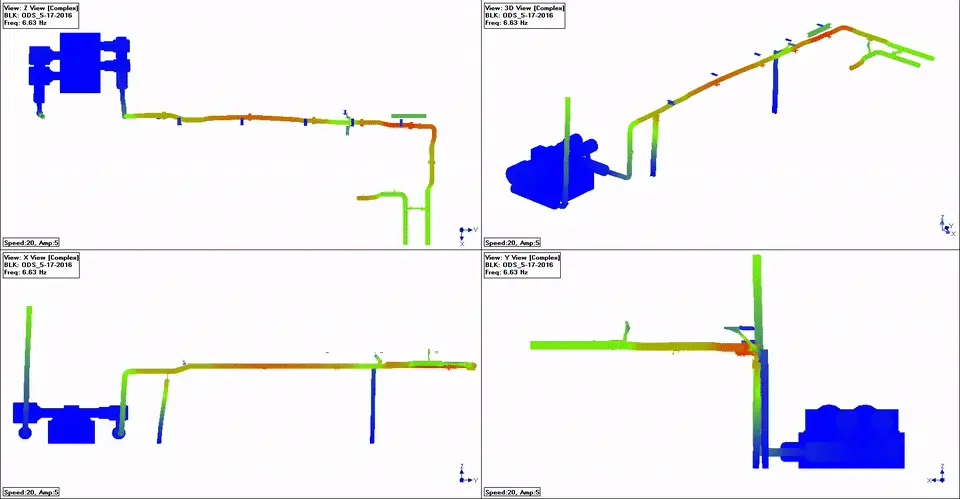

- Findings: Resonance was identified with the compressor operating speed. This was due to a discharge piping structural natural frequency.

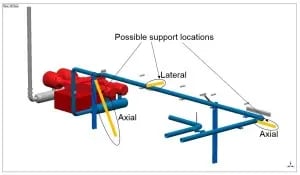

- Impact: The findings suggested the installation of piping supports were necessary along the length of the discharge pipe to shift the piping natural frequency away from the running speed. A Finite Element Analysis calibrated to the data collected on site to develop a solution with a greater chance of success upon implementation was recommended to the customer.

Locations for suggested pipe supports.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Troubleshooting a Pipeline Renewable Diesel Screw Pump

Elevated vibration levels were causing a pipeline company screw pump problems.

Case Study

Petrochemical Ammonia Recip Compressor Piping Troubleshooting

Excessive motion by the discharge piping of a petrochemical ammonia reciprocating compressor startled the operators.

Case Study

Oil Tanker Pumping Station Screw Pump Troubleshooting

Troubleshooting a new oil tanker pumping station in Colombia consisting of 4 screw pumps. Specialized testing revealed that piping natural frequencies were to blame.