Aeroderivative

Gas Turbine Vibration Problem At Idle

MSI Troubleshooting Consultants Determine Resonance is Causing High Vibration at Idle Conditions, and Provide a Solution

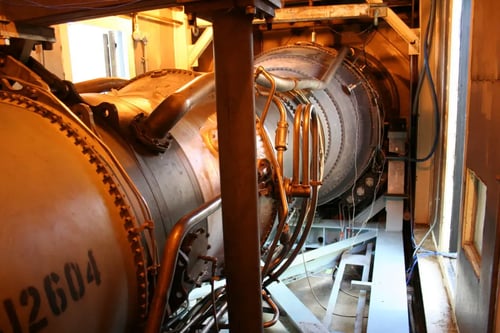

A 22 MW aero-derivative gas turbine in peak generation service at a combined cycle plant had a rigid power turbine-to-generator coupling replaced with a flexible diaphragm coupling. Following the modification, high vibration was detected at the power turbine section of the gas turbine, but only at idle speed. In addition, ever since the original package installation in 2001, elevated axial vibration was reported on the outboard bearing housing of the generator during the ramp-up.

MSI’s troubleshooting consultants performed a combination of experimental modal analysis (EMA) testing and operating forced response testing on all available portions of the engine-generator. The log amplitude of the frequency response function (FRF) plots resulting from the EMA testing was plotted versus frequency. The broad-band peaks in the FRF plot indicated the natural frequencies of the gas turbine's structural system. The operating forced response test provided the data needed to create operating deflection shape (ODS) animations of the installed system.

Operating Deflection Shape (ODS) at idle load, operating at 59.2 Hz

The ODS animation showed the relative motion (amplitude and phase) in an exaggerated (but to scale) fashion of each of the 420 measurement locations on the gas turbine engine, support structure, generator, and skid. In addition, transient and continuous monitoring testing was performed on the gas turbine while gathering casing and generator shaft vibration, strain gage data on the Power Turbine support structure, and torque data from the coupling.

Modal analysis animation at 48.4 Hz while offline

|

While the turbine was not operating, a natural frequency was detected at 48.4 Hz, showing a bending/ axial mode of the entire turbine. This mode had a forward precessional component that shifted to about 60 Hz once the power turbine supports (laterals and bottom support) were loaded. |

Based on the specialized vibration, structural strain gage and torque test results, MSI troubleshooting engineers determined that the problem root cause of the high vibration at the power turbine (PT) casing during idle operation was due to a resonance at 60 Hz. While the turbine was not operating, this natural frequency was detected at 48.4 Hz, showing a bending/ axial mode of the entire turbine. This mode had a forward precessional component that shifted to about 60 Hz once the PT supports (laterals and bottom support) were loaded. Additionally, the newly installed coupling had a strong lateral natural frequency with only a 0.7% separation margin from the high speed compressor running speed (N2) at idle (amplification factor of 24).

Equipment for testing included accelerometers and strain gages

MSI recommended the following fixes in order to reduce the radial vibration of the power turbine during idle operation:

- Pre-load the center support under the turbine by adding shims. This solution was tested/ evaluated by applying tension load on the I-beam and observing reduced vibration and support structure strain gage measurement change.

- Verify the torque applied on the hold-down bolts of the pillow-blocks supporting the turbine.

- Shift the coupling lateral mode away from the N2 by increasing the N2 speed by 7%.

In order to reduce the axial vibration of the generator during the ramp-up and coast-down, one potential solution was to increase the stiffness of the IB and OB ends. However, since these parts were provided with ribs, a major modification of the structure risked providing only a small increment in stiffness. Therefore, in MSI’s opinion, the best solution was to accelerate ramp-up to minimize the operating time at the axial generator casing resonance condition at approximately 3060 rpm (the axial resonance was shown to not harm the generator rotor).

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.