Operating Deflection Shape (ODS) Testing Uncovers a Turbine Disk Resonance

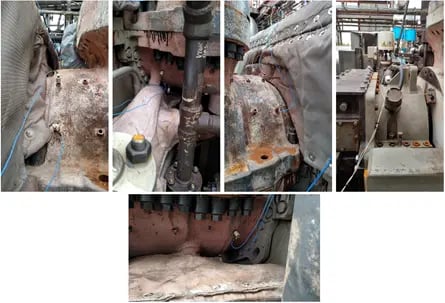

MSI conducted vibration testing of a rerated medium power steam turbine in US-Mideast. The main purpose of the testing was to evaluate a potentially resonant bladed disk vibration of the control stage within a specified speed range.

Continuous Monitoring: Accelerometers along plane of stage circumferentially mounted

MSI performed specialized vibration testing that included experimental modal analysis (EMA), continuous monitoring, and operating deflection shape (ODS) characterization. This testing indicated that harmful vibration from resonance of the control stage (energized by nozzle pass excitation) was transmitted to the turbine casing. To temporarily address the issue, the lower boundary of the no-run zone was extended and no significant evidence that operation above a certain rpm provided any significant reliability problem for the turbine.

- Work Performed

- Methods: EMA, ODS, Condition Monitoring

- Results/ Solution

- Findings: Vibration from resonance of the control stage (energized by nozzle pass excitation)

- Impact: No-run zone was extended & operation above a certain rpm did not provide a significant reliability problem

Acceleration data filtered at Nozzle Pass Frequency

FFT of an accelerometer on the turbine casing

Operating Deflection Shape at 172 Hz (1xN)

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.