Practical Strain Gauge Application In The Field

By Eric Olson

Properly applied strain gauges can be very useful for better understanding and solving torsional, bending, or axial vibration issues in rotating machinery by uncovering valuable information. They can also help accurately determine the horsepower required by the driven machine. Strain gauges are also used to measure the loads, moments, and stress levels on stationary structural components such as casings and piping.

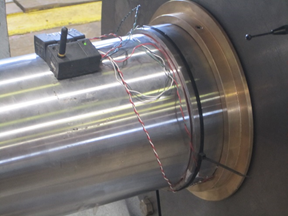

Torsional Rotordynamics: Briefly stated, torsional vibration results in the twisting of shaft sections (think of a barber pole). Vibration measurement techniques used to measure lateral and axial vibration (accelerometers, proximity probes, and high-speed cameras) are not applicable for torsional rotordynamic issues. This case history provides more information about how strain gauges can transmit the torsional vibration via a Radio Frequency (RF) transmitter to help address a shaft and coupling failure issue.

A past example of resolving a shaft failure issue involves a mining company’s newly installed vertical raw water pumps. In this case history, the excitation source was one-half the diesel engine's running speed due to engine mistuning.

Piping and other structures: Strain gauges are also very useful for addressing possible pipe strain-related problems. Excessive pipe strain can distort machinery casings enough to adversely impact the internal running clearances between rotating and stationary parts leading to rubbing, high vibration, and reduced operating life. In this case history, MSI uses strain gauges along with other test techniques to help solve a high structural vibration issue in a large feedwater pump system.

This case history describes how strain gauge data, among other test results, helped uncover a gas turbine generator gearbox support cracking problem.

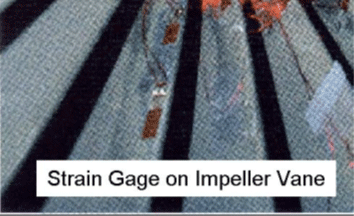

Internal Machinery Components In this case history, miniature strain gauges, and RF telemetry are used to measure strain on a compressor impeller blade while the compressor operates. The data helped the manufacturer revise the compressor family design to address an operating range limitation due rotating stall.

Caution – Proper surface preparation, strain gauge installation, and use require specific expertise and experience, especially when used on rotating components.. Please contact MSI for additional information.