Feed Pump and Pipe Strain Testing

A nuclear power plant was trying to understand why their new feed water pumps exhibited high vibration amplitude (1x rpm) at the drive end (DE), showed step changes in vibration over time, and demonstrated inconsistent results associated with the alignment before and after shut-downs.

- Problem Statement (Challenge)

- What (type of machine): Single Stage Double Suction Feed Water Pump in Nuclear Service

- Where (State/ Country): Wisconsin

- Why (problem/reason): A nuclear power plant was trying to understand why their new feed water pumps exhibited high vibration amplitude (1x rpm) at the drive end (DE), showed step changes in vibration over time, and demonstrated inconsistent results associated with the alignment before and after shut-downs. The plant wanted a second opinion on whether it was safe to continue running the pumps or take the entire plant off line for a costly and unexpected outage.

- Work Performed

- Vibration Testing Methods: Experimental Modal Analysis (EMA), Condition Monitoring, Operating Deflection Shape (ODS), and Strain Gauge Installation

- Results/ Solution

- Findings: The high vibration of the pump DE was due to excessive piping strain on the suction and discharge nozzles measure with weldable strain gauges. In this particular case, the pump casing was acting as an anchor support for the piping. When the piping load was applied, the south end of both pumps was pushed downward, changing the angular alignment of the pump and motor shafts. In addition, changes in the phase angle at the DE of Bravo FWP indicated a change in the rotor heavy spot.

- Impact: The findings suggested that since no bearing damage or shaft overheating was observed, MSI determined that the Bravo FWP can be maintained in service. During a future outage, MSI recommended that the loads for the suction and discharge piping should be corrected based on a piping flexibility analysis.

Strain gauges installed

Strain gauges installed

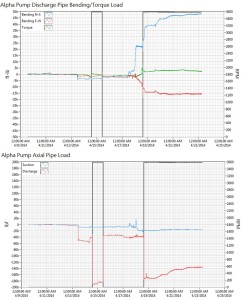

Top view bending loads. Bottom view axial loads.

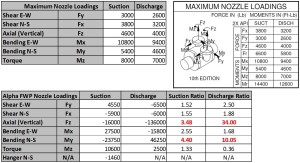

Nozzle loads results summary table using strain gauges

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.