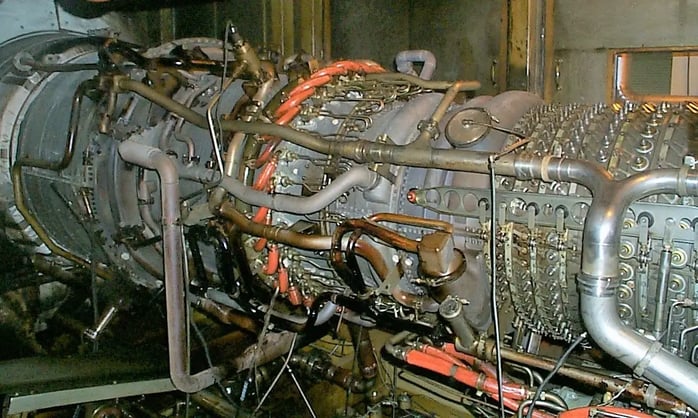

Aeroderivative Gas Turbine And Gearbox/Genset

MSI Engineers Track an Elusive Gas Turbine Problem to the Root Cause, and Provide a Simple Solution

MSI troubleshooting consultants were called on behalf of a customer who had seen a large increase in the vibration levels of a particular Gas Turbine Generator Set being used to supply power to a large pharmaceutical facility. The increase in gas turbine generator vibration levels was serious enough to warrant shutdown. This power facility was used to meet much of the electrical power needs of the entire complex and any loss of generating capacity translated straight into increased electrical operating costs because of the need to buy power from the grid at a time of the year where such purchases were particularly expensive. The plant wished to continue operation another 3 months, until there was a planned shutdown.

|

Because of MSI’s experience conducting such tests, the generator was shut down for only an hour in order to install the telemetry system. |

The OEM had not been able to find the reason for the difficulty. Therefore MSI engineers were called in to help diagnose and fix the excessive gas turbine vibration. The customer had noticed that the large increase in the overall vibration was particularly troublesome in between the gas turbine and the generator. They suspected that the problem was a torsional natural frequency of the gearbox. MSI performed specialized vibration testing techniques using strain gauge testing on the generator shaft and sophisticated radio telemetry system. Because of MSI’s experience conducting such tests, the generator was shut down for only an hour in order to install the telemetry system.

The vibration testing was to focus on shaft torsional oscillation, but showed that the torsion did not cause the high gear box vibration. MSI continued testing the gas turbine and was able to quantify the vibration levels with increasing load. Based on the shape of the vibration spectrum, the strength of the vibration appeared to be associated with a natural frequency resonance. However, impulse testing on exposed components detected no strong natural frequencies near 1X or 2x gear mesh. It was also noted that the vibration increase was sensitive to load level. In light of this, the sudden increase in vibration suggested a possible turbine shaft or casing crack that opens up under increasing load. This crack could open up further as the load transmitted through the gear box was increased. Bump or impact tests did not indicate this crack, but vibration measurements at many locations at various loads made it apparent.

In order to be completely certain that this was the most likely cause, MSI engineers also tested the electrical generator to confirm that the problem was not in the generator or electrically based. This testing revealed nothing unusual in the phase-to-phase characteristics of the turbine generator system, and left a crack as the most likely cause of the problem.

On the recommendation of MSI troubleshooting engineers, dye penetrant testing of the gas turbine gear box was conducted. The dye penetrant testing revealed that a crack had formed on the foot of the gear box casing. The crack was welded shut and subsequently the vibration of the gearbox was reduced to earlier acceptable levels. This work allowed the end user to continue power generation during a critical portion of production.

In addition to knowledge of the gas turbine, the staff of Mechanical Solutions, Inc. has background and experience in the analysis and testing of many popular aeroderivative gas turbines. One of MSI’s principals was one of the design analysis team-members for the original ground-based and marine-based conversions of a popular turbine. Generally, problems with these units are installation or system related. MSI’s ability to separate and evaluate rotordynamic, casing, and support structure effects allows such problems as well as any warranty issues to be quickly identified, such that responsibilities can be determined, and appropriate fixes can be developed and implemented.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.