Wastewater Treatment Blower High Frequency Audible Tone

Motion Magnification Can Quickly Diagnose Even High Frequency Problems

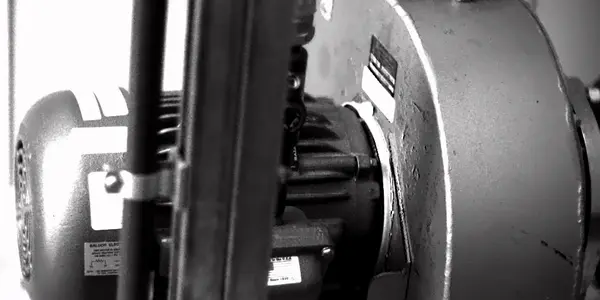

What do you do when you have a small blower that’s as loud as a thunderclap – all the time? In this interesting case, we present a comparison of motion amplified video along with accelerometer-based data acquisition to develop an Operating Deflection Shape (ODS) model, resolving a 120dB nuisance. A small, constant speed blower was emitting an uncharacteristically loud (120dB) audible frequency during operation. The elevated noise, measured at the shaft and casing of the newly installed blowers, was due to a strong excitation at vane pass frequency (VPF). A structural natural frequency of the volute was excited by what is often (and is in this case) the most powerful forcing function generated by these types of blowers, which is the vane pass frequency of eight (8) times the rotating speed. Also of note, the blowers were oversized for their required service, hence their operation was far back on the head/flow curve, well off the Best Efficiency Point (BEP). This operating point was likely causing vortexing at the vanes, exacerbating the vane pass effect. Diagnostic tools included MSI’s VibVue® system. High-speed, high-resolution video was recorded while the blower was in operation. This video was analyzed to determine notable frequencies, which included the operating speed (59.25 Hz/3,555rpm) and the vane pass frequency (474Hz/28,440cpm). Amplifying the motion at the vane pass frequency resulted in a clear depiction of a blower housing “plate” mode, where the housing is undulating back and forth, much like a speaker.

This conclusion correlated well with accelerometer data collected at many points on the machine (282 data points in all). The accelerometer data was compiled into a model of the machine, and then amplified, similar to the motion amplified video, albeit much slower and more cumbersome. This Operating Deflection Shape (ODS) revealed a similar mode shape at the vane pass frequency of 474Hz.

Recommended solutions to the problem included resizing the fan for the current requirement or altering the impeller design to reduce the excitation forces, or bracing the fan housing to stiffen it and reduce the resultant speaker-effect.

Read About:

Pre-Construction Analysis For Singapore's Marina Barrage

Resolving Vertical Pump Lineshaft Failures

Water Filtration Plant Energy Dissipation Valve Vibration

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Pipeline Pumping Station High Frequency Resonance

This case study looks at a nagging problem within the pipeline industry - small bore piping resonance, and shows how to solve it with video vibration tools.

Case Study

Design Assessment Mitigates Risk

A design assessment was carried out in an effort to prevent potential premature bladed disk and impeller fatigue failures of three newly installed critical compressor trains.

Case Study

Development of a Prototype Vacuum Blower

A major aerospace equipment supplier/manufacturer needed to design and prototype an FAA-approved vacuum generator for use on commercial aircraft.