Vibration Testing of Two Induced Draft Fans

Mechanical Solutions, Inc. (MSI) was contracted by a power generation company to solve excessive vibration problems on two newly installed Induced Draft (ID) fans. High vibration levels at one times (1x) running speed were reported that exceeded trip levels during start-up. Traditional vibration analysis used by others had not successfully resolved what initially appeared to be a straight-forward unbalance and/or misalignment problem.

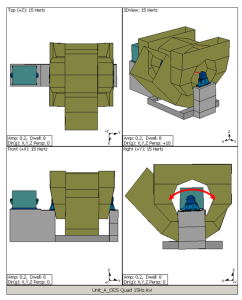

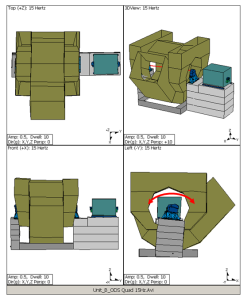

MSI collected detailed natural excitation vibration data on the bearing housings, bearing supports, bearing sole plates, concrete pedestals and concrete floor pads. MSI uses a specialized operating forced response vibration technique that allows the data to be used to produce very detailed animated operating deflection shapes (ODS) of the fan system. The ODS animation shows the relative motion of the various system components in an exaggerated fashion to help efficiently identify the root cause(s) of the problem. MSI also performed impact modal testing while the units were operating using its Time-Averaged Pulse (TAP™) technique to determine the natural frequencies and mode shapes while the bearings are energized (taking into account the sleeve bearing stiffness).

Both fans showed very high vibration amplitudes in the horizontal direction on the outboard bearing housings and on the outboard piers. Vibration spectra showed several harmonics of the running speed, the highest peaks being at 1x and 2x running speed.

ODS tests showed horizontal rocking motions of both inboard and outboard piers in both fan installations. This horizontal motion was more pronounced in fan B. There was also evidence of looseness of the bearing assemblies (housing, support and soleplate), especially in the outboard bearing assemblies of both fans. MSI determined that the rotor critical speed had shifted downward toward the running speed of 15 Hz, due to the high flexibility of the rotor supports and pedestals. This rotor critical speed and the structural resonance near 15 Hz interacted with each other and were the likely cause of the modulated orbits of the fan B rotor. Rotordynamic analysis showed that lateral stiffening of the outboard pier would detune the 1x resonance sufficiently to decrease the vibration amplitude to acceptable levels.

The root cause of the excessive vibration was found to be the flexibility of the soil under the base mat of the piers. MSI recommended that the horizontal stiffness of the outboard bearing pier and support (base mat and soil) assemblies should be increased substantially in order to de-tune the resonance condition of the rotor critical speed and the pier structural natural frequency with the running speed of the units. All of the bearing housing and support assemblies should be tightened and stiffened as practical to minimize overall vibration.

The soil flexibility root cause would have been extremely difficult and expensive to determine without the benefit of MSI’s specialized and well-proven troubleshooting approach. A design assessment, performed before installation, could have been used to avoid the problem.

Unit A wire frame ODS at 1x (15 Hz)

Unit B wire frame ODS at 1x (15 Hz)

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.