Solving A

Below-Ground VTP Resonance With Specialized Testing & Analysis

Two vertical turbine pumps (VTPs) with 45 ft. (13.72 m) long column assemblies installed in a nuclear facility were suffering from premature wearing of the line shaft bearings and shaft sleeves leading to frequent and costly repairs. MSI was contracted to successfully solve the problem. The two FFT spectra plots (in logarithmic scale) shown below led to the initial conclusion that the root cause was a below-ground resonance.

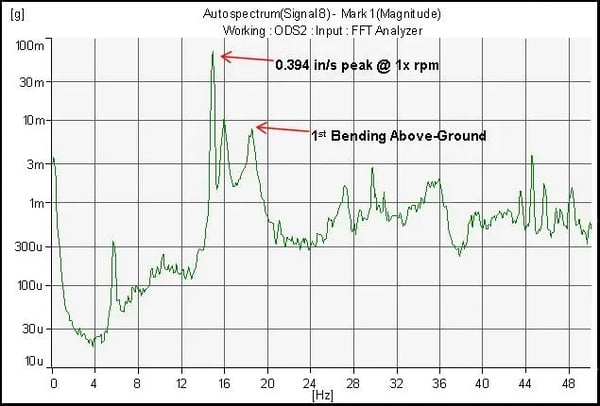

Vibration spectrum plot from a motor bearing measurement. Without further investigation, a classic reed frequency problem would have been suspected. However, the 3rd bending below- ground mode can be seen.

Vibration spectrum plot from a motor bearing measurement. Without further investigation, a classic reed frequency problem would have been suspected. However, the 3rd bending below- ground mode can be seen.

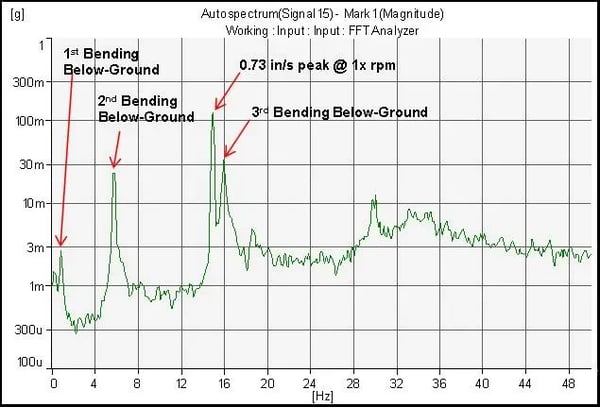

An accelerometer mounted on the suction bell flange shows that the 3rd below-ground mode (15.9Hz) is only 7% away from the 1x running speed (14.9Hz, 894rpm) excitation source.

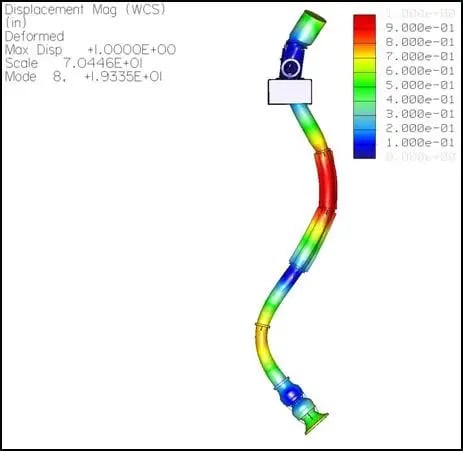

In order to design a solution and avoid costly and time-consuming trial and error problem solving, MSI performed an operating deflection shape (ODS) test. The ODS test results were used to calibrate a finite element analysis (FEA) model. The FEA model was used to determine the optimum solution.

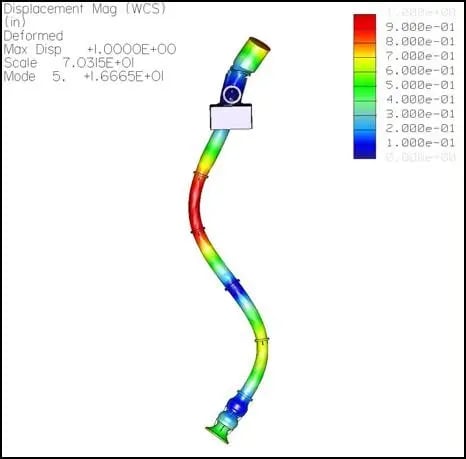

Click to view ODS animation showing the 3rd below ground mode at 15.9Hz (only 7% separation margin from the 14.9Hz pump running speed). A picture is worth a thousand words, but a properly performed detailed ODS animation is worth a thousand pictures in helping to understand and explain system dynamics problems. Motion is exaggerated but to scale. The problematic below-ground 3rd bending is clearly shown.

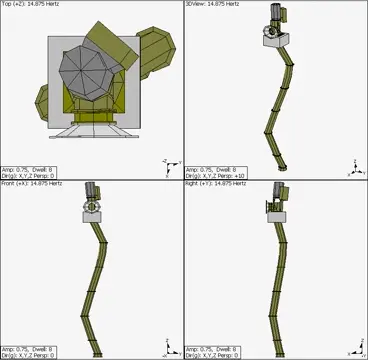

Freeze frame of the FEA model mimicking the problem. Solutions were evaluated using the test-calibrated FEA.

One solution option was to add an MSI specified number of one inch thick ribs to the upper column shifting the 3rd bending mode upward by 16% (well away from running speed). The second option (not shown) was to shorten the column pipe by an MSI specified number of feet, which shifted the offending mode even higher.[/caption]

In both cases, the analysis indicated that the modifications would not create a resonance issue with other system natural frequencies. The customer elected to shorten the column after MSI determined this was hydraulically acceptable.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.