Shifting A Natural Frequency Away From Running Speed

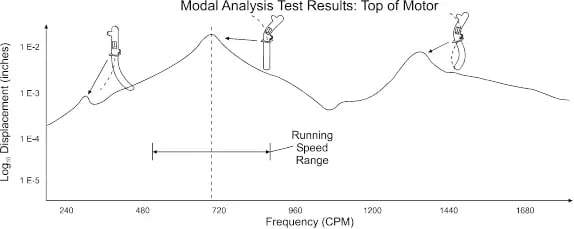

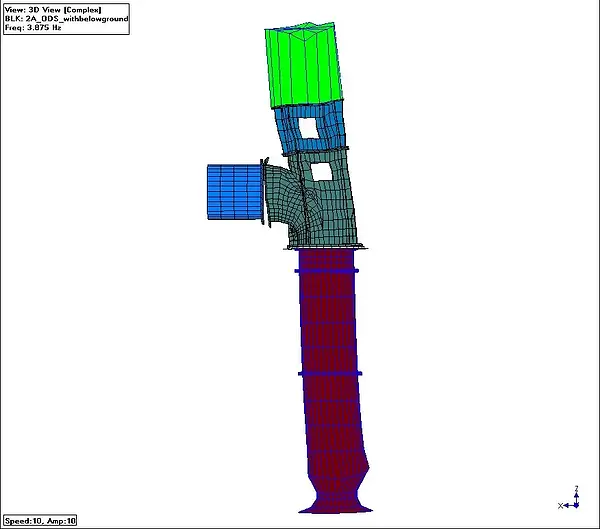

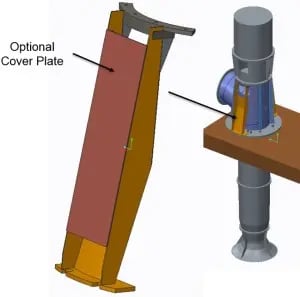

A Middle East power plant had a serious 1X running speed vibration problem with some vertical turbine pumps (VTP) for service water and associated piping. Although these pumps were not central to the production of power, the plant could not run for extended periods without them, and motor bearing and discharge head mechanical seal problems were causing chronic pump shut-downs. A rotor critical speed problem was suspected by the plant. Testing showed that no shaft critical speeds were near running speed, but that a combined motor/ discharge head / floor / piping natural frequency was within several percent of running speed. Modification of the motor frame with bolt-on gussets and closing of the discharge head window with a removable stiffener plate shifted the natural frequency of the system up enough to avoid resonance, and bring vibrations down to acceptable limits.

FRF plot from an accelerometer at the top of the motor.

Overall view of the service water pumps.

Modification implemented on a VTP having structural natural frequency problems.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.