Pre-Construction Analysis For Singapore's Marina Barrage

Marina Barrage is part of a comprehensive flood control system to eliminate flooding disasters in Singapore. The two-fold responsibility of Mechanical Solutions, Inc. (MSI) was to ensure that: a) the flood control motors, gearboxes, and pumps would not have any life-limiting vibration problems; and b) the pump systems would not cause vibration in the pump house and adjoining visitor’s center including annoying window vibration when the pumps were operational.

View of Marina Barrage from the 45th floor of the Marina Bay Sands hotel. Foreground is fresh reservoir water. Background is ocean water.

View of Marina Barrage from the 45th floor of the Marina Bay Sands hotel. Foreground is fresh reservoir water. Background is ocean water.

Marina Barrage is a centerpiece of Singapore. In addition to providing around 10% of Singapore’s water supply, family attractions include the reservoir for boating activities, a visitor’s center and gallery, walking trails, a gift shop, waterpark, and an open grass field on the pump house roof that is the size of four football fields. During heavy rain, the series of nine crest gates at the dam open to release excess storm water into the sea when the tide is low. At high tide, seven pumps drain excess storm water into the sea. At the time of MSI’s analysis work, the pumps were the world’s largest flood control pumps ever designed, each with the ability to drain an Olympic-sized swimming pool in under one minute.

Axial flow propeller pumps with diffusers during the installation process.

1.6 MW horizontal motors, right angle gearbox, and the top of the vertical axial flow pumps that operate at 120 RPM.

Visitors can see the operating equipment through the pump house's large windows. Marina Barrage is a favorite field trip location for local school, families and tourists.

Under a contract from the European pump manufacturer, the specified pump system finite element analysis (FEA) goal successfully ensured that no structural or torsional rotordynamic natural frequencies of the motor, gear, pump, and nearby piping and foundation fell within +/-15% of excitation frequencies. Examples of these frequencies include 1x running speed, 2x running speed, impeller blade and diffuser vane pass, gear mesh, and line frequency related forces. The work was the equivalent of a level 3 analysis from Hydraulic Institute/ANSI 9.6.8 entitled “Guideline for the Dynamics of Pumping Machinery” and was used to guide finalization of the pump design.

The next step under a contract from the Singapore engineering firm was to perform a structural and acoustic dynamics analysis of the pump system as it would be installed in the pump house and visitors center. Based on the detailed analysis of the pump, foundation, waterway, and surrounding building, MSI determined that all of these components were structurally adequate from a vibration and acoustics point of view.

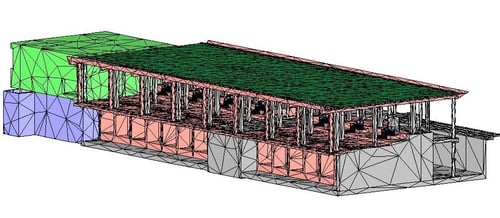

FEA model that includes the pump house structure and roof, seven pump systems, and adjoining visitors center. The dynamics analysis work needed to include the effects of various fluid levels and varying numbers of operational versus non-operational pumps. Note: MSI's use of P-elements in this advanced model allowed for much more efficient modelling because the P-elements can be meshed more coarsely than the industry standard H-elements. Exceptional fidelity is maintained because of the high order polynomial (P) shape functions.

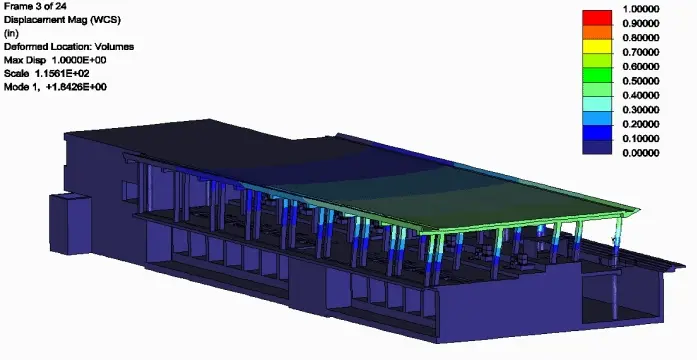

The flood control system building modal analysis combined with the seven pumps predicted a natural frequency close to the running speed of the pumps (2Hz). The mode shape of this natural frequency at 1.84 Hz showed the pump station roof with horizontal sway motion. To determine if this mode would result in high vibration levels, a conservative forced response analysis was performed, in which the worst case imbalance loading was applied on the top of each pump foundation, rather than at the pump impeller locations, in order to maximize the effect of the excitation forces. The predicted vibration levels at the station floor and at the roof, where the maximum motion would be felt, were well below the specification allowables. In addition, stress levels were also evaluated under this potential resonance condition, and the stresses in the reinforced columns were found to be negligible. Several natural frequencies of the roof were also predicted close to blade and vane pass frequency, but these modes also had similar low vibration amplitudes. Therefore, in MSI's opinion the construction of the Marina Barrage Building did not require any modification to address the roof modes close to the pump running speed and other excitation sources, and vibration should not be noticeable to visitors.

One of many analysis animations created and evaluated by MSI engineers. The animation shows exaggerated building deformation due to natural frequency excitation. MSI concluded that while this natural frequency was close to the pump operating speed, it was not in danger of being excited.

Thanks to the analysis MSI performed, the pumphouse and the visitor center were able to be installed with zero vibration or acoustic problems. The citizens of and visitors to Singapore are able to enjoy a trouble-free facility.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

New Orleans Flood Control Pumping Stations Vibration Analysis

MSI was recommended to analyze flood control pumping station system dynamics, including evaluation of the platform design with regard to vibration.

Case Study

Water Treatment Plant Pumps Fail Vibration Specification During Commissioning

A contractor putting together a water treatment facility encountered vibration issues with various pumps during commissioning.

Case Study

Newly Installed Water Treatment Plant Pumps Cavitating & Vibrating

A county water treatment plant heard “cavitation-like noise” from their newly installed pumps and called MSI for help.