Nuclear Generator Stator Cooling Pumps Specialized Vibration Testing

A nuclear power plant’s generator stator cooling pumps had experienced random elevated vibrations during steady conditions since their installation in the 1980s. These typical vibration issues required fine-tuning of the alignment to reduce the overall vibration amplitude to acceptable levels after every outage.

- Problem Statement (Challenge)

- What (type of machine): Generator Stator Cooling Pumps Nuclear Service

- Where (State/ Country): New Hampshire

- Why (problem/reason): A nuclear power plant’s generator stator cooling pumps had experienced random elevated vibrations during steady conditions since their installation in the 1980s. These typical vibration issues required fine-tuning of the alignment to reduce the vibration to acceptable levels after every outage. A recent coupling change and baseplate re-grout resulted in elevated pump vibrations. Instead of developing a new temporary remedy for every outage, the plant decided to find the root cause and develop a permanent fix to eliminate the need for alignment fine-tuning. This was done via MSI’s vibration testing methods.

- Work Performed

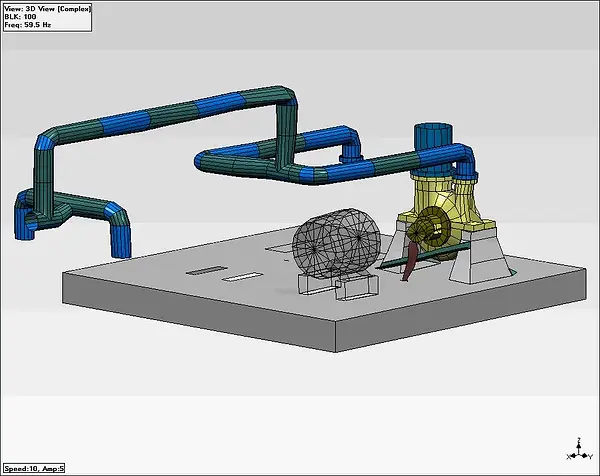

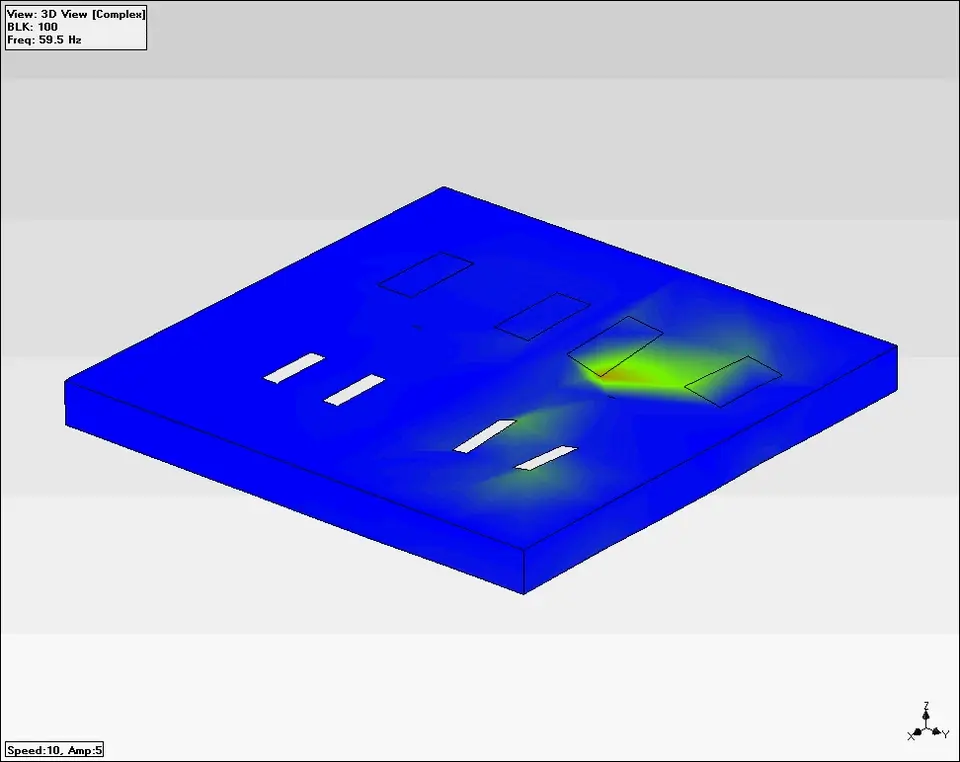

- Methods: Experimental Modal Analysis (EMA), Continuous Monitoring, and Operating Deflection Shape (ODS)

- Results/ Solution

-

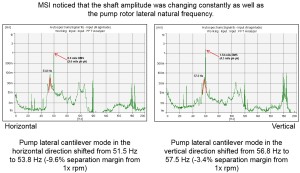

- Findings: The root cause for the erratic vibration was a combination of multiple problems, all interacting with each other. The first issue was the flexibility and looseness of the bearing tower support, shifting the pump shaft's lateral natural frequency closer to the pump running speed, which is the excitation source. The second issue was the deformation of the baseplate underneath the pump support due to voids in the grouting. The third issue was looseness at the pump discharge flange and pipe connection due to excessive movement from flexibility in the discharge piping. These factors explain why maintenance personnel had difficulty aligning every time the pumps were shut down.

- Impact: The plant addressed the lack of stiffness with a more rigid bearing housing support, the discharge pipe vibration with additional pipe support, and filled the baseplate voids. The plant no longer has to worry about future unscheduled outages or labor-intensive pump alignments to get the vibration below acceptable levels.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.

.webp?width=600&height=476&name=Nuclear%20Generator%20Stator%20Cooling%20Pumps%20Specialized%20Vibration%20Testing%20(2).webp)