Rotordynamic Analysis Of A

Multi-rotor Gas Turbine

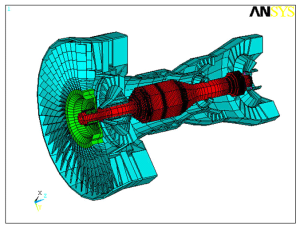

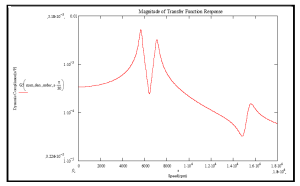

An area of concern for gas turbine OEM’s and end users is the effect of casing and structural supports on the rotordynamic response of multi-rotor systems. MSI has conducted sophisticated analysis of such problems utilizing the latest technology available in Finite Element Analysis (FEA) and rotordynamics. Figure 1 shows an aircraft gas turbine FEA model developed utilizing ANSYS. By conducting a forced response analysis of a proposed weight reduction of the casing, the frequency dependent response of the structural forces and vibrations at the bearing support locations was determined. Figure 2 shows the transfer function representation of this frequency dependent response.

Figure 1. FEA Model of Gas Turbine Casing and Dual Rotors.

Figure 2. Transfer Function Representation of Hypothetically Reduced Weight Casing Support Stiffness.

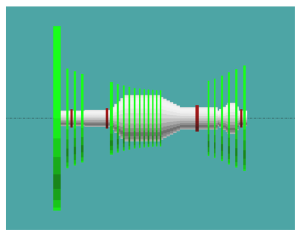

The transfer function was then incorporated into a multi-rotor rotordynamics model for analysis. Figure 3 shows the rotor model created utilizing a commercially available suite of rotordynamics codes. This model incorporated the structural supports as determined with ANSYS with the full multi-rotor system. The resulting multi-level model was able to analyze the engine for forced response, lateral stability and both damped and undamped mode shapes.

Figure 3. Rotordynamic model of multi-rotor system with transfer function representation of the casing support incorporated into the bearing support stiffness.

Based on this more complete model, issues associated with structural supports and their effect on lateral rotordynamics can be properly assessed.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.