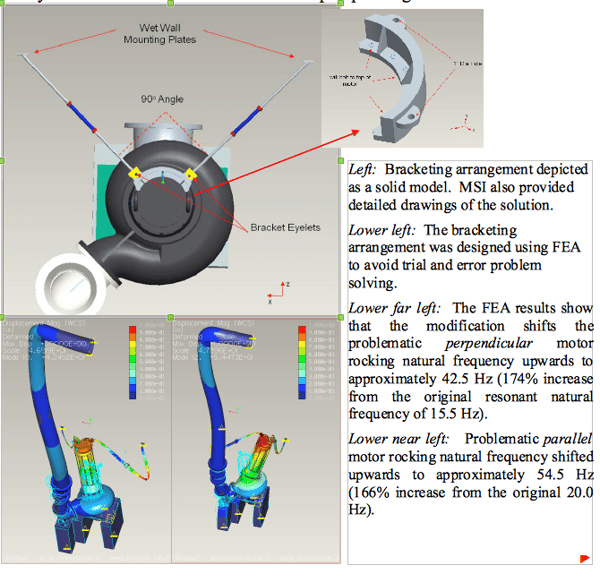

Fixing Resonance In A Submersible Dry Pit Pump System

Four recently installed vertically mounted, variable speed driven, dry pit submersible pumps suffered from high vibration. In one case, the concrete support piers exhibited cracking damage. MSI was contracted to perform specialized field testing and analysis to characterize the problem. Finite Element Analysis (FEA) was used to design an effective solution.

The following combination of issues was identified based on MSI’s thorough experimental modal analysis (impact) testing performed while the motor/pump system operated, augmented with Operating Deflection Shape (ODS) testing and pressure pulsation testing using dynamic pressure transducers:

-

Pressure pulsations are generated in the suction line because of low suction pressure (low level of the wet well) and suction re-circulation at the impeller inlet caused by low flow operation.

-

Excessive flexibility of the pump casing /volute.

-

Structural natural frequencies close to or within 1x rpm and Vane Pass Frequency (VPF) range (2x rpm).

-

Acoustic natural frequencies near 1x rpm and VPF.

-

Cavitation noise, which was present but was not at a level to cause metal removal damage.

The near-term fixes were to lock out rotational speeds that were resonant with structural natural frequencies (i.e., items 2, 3, and 4). Locking out these speeds on a permanent basis was not an acceptable long-term solution. MSI also recommended that the originally specified 10-foot wet well level be maintained to resolve items 1 and 5.

The longer-term solution was to shift the offending natural frequencies so they would not be resonant with 1x rpm and VPF.

Click to view animation.

MSI used FEA, calibrated by the ODS and impact test results, to design an appropriate solution. MSI recommended using two horizontally stiff beams with threaded adjustment and a locking nut, 90 degrees apart. The supports were located ±45 degrees from the suction nozzle towards the wet well wall, rigidly attached to the top of the motor, and firmly anchored to the wall to reduce motor/pump casing deflection.

NOTE: The problem could have been avoided by specifying and performing a pre-construction pump/motor/support/piping dynamics analysis.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.