Eddy Current Drum Coupled Motor High Vibration Analysis

After being refurbished, the motors experienced excessive vibration at certain pump speeds, thereby restricting the pumping system’s ability to handle various flow ranges. A permanent fix was sought out since pump rental costs significantly increased the cost of operating the pump station.

- Problem Statement (Challenge)

- What (type of machine): Eddy Current Drum Coupled Motor to a Centrifugal Non-Clog Pump

- Where (State/ Country): Florida

- Why (problem/reason): A 35-year old pump station moving up to 43 MGD of raw wastewater to the city’s treatment facility via two 1,500-hp high-capacity pumps for wet weather flows was experiencing vibration issues. After the motors were refurbished, excessive motor vibration occurred at certain pump speeds, thereby restricting the pumping system’s ability to handle various flow ranges.

- Work Performed

- Results/ Solution

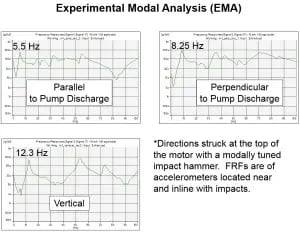

- Findings: MSI's specialized vibration testing performed showed that the rocking structural natural frequencies of the motor were in resonance when the pump operated at the corresponding speeds. Both of these natural frequencies were determined to be in resonance with the running speed forcing function. The vibration levels were not greatly excited due to the currently well-balanced rotor. From experience, this vibration would be amplified in the future as the imbalance load increases.

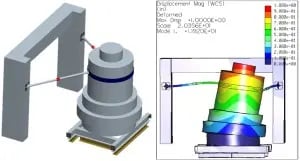

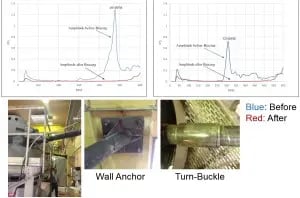

- Impact: MSI's vibration test results were used to calibrate an FEA model to determine the effectiveness of various methods to increase the structural stiffness of the top of the motor in order to shift the problematic natural frequencies up to a safer separation margin of 15% above the running speed frequency. Independent vibration verification before and after the modification installation showed a clear decrease in vibration throughout the pump operating speed range. MSI’s recommended fix worked as intended and restored safe operation at the much needed higher flow capacity of the plant. The customer was able to terminate its rental of back-up pumps, which were required to meet the system demands.

Emergency rental pumps outside of the station.

Impact test results. Also known as bump test.

Image of FEA Model and Modal Results.

Picture of Modification and Vibration Results.

Animation.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.