Designing An Oscillating Water Column Wave Energy Converter

From Concept to Deployment

MSI is often called upon to design turbomachinery that is unique in concept, performance level, or some other distinguishing attribute. This particular design was no exception, with a brilliant approach to capturing wave energy.

MSI was contracted by Wave Swell Energy to design the turbine assembly for an oscillating water column (OWC) wave energy converter (WEC). They have since deployed this demonstration unit off the coast of King Island, Tasmania and it is currently generating power. It will supply electricity up to a maximum of 200kW to the King Island electricity grid.

Oscillating Water Columns

Interested in some of our other turbomachinery designs?Check out our blog post

|

OWCs work by turning the rising and falling water surface into a piston which drives air through a turbine. It is a renewable energy technology that promises to be energy and cost efficient, reliable, and low maintenance, if properly deployed.

The turbine, as one would expect, is a key component of the system, which also requires a large concrete structure anchored to the seabed. A box portion of the structure acts as sidewalls to the piston chamber. The concrete structure also supports the turbine-generator above the water surface and houses necessary control equipment.

The Turbomachine Design

The bladed disk of the turbine was designed with cost, weight, and the environment in mind. A relatively simple tried-and-true radial entry T-slot blade attachment method was incorporated. The shape of the turbine blade and stator vanes were designed by other aerodynamic experts. MSI evaluated the stresses due to spin, pressure, resonance, and operational vibration loading.

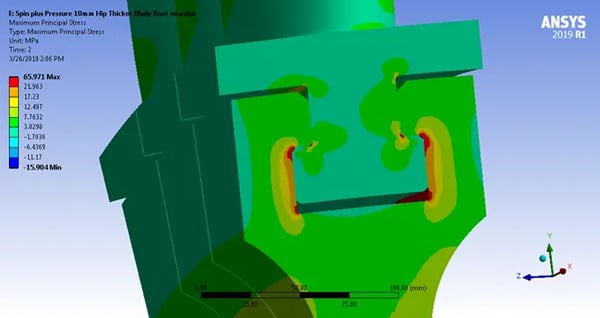

Finite Element Analysis (FEA) of the turbine root demonstrated acceptable stress levels

Finite Element Analysis (FEA) of the turbine root demonstrated acceptable stress levels

Bladed-disk dynamic behavior due to interaction between turbine blades and stator vanes

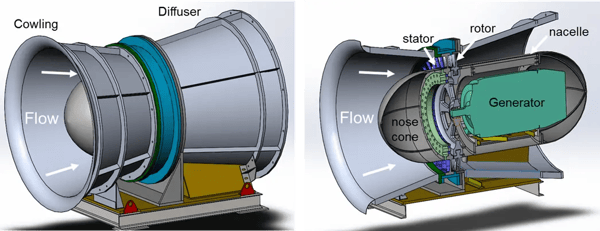

Lightweight, low-cost aluminum alloy materials, well-suited for the marine environment, were selected. Based on the relatively low power and lightweight turbine wheel, MSI determined that the turbine could be close-coupled to the commercial-off-the-shelf generator. This allowed for a compact arrangement of the rotor-stator-generator assembly, saving weight, cost, and reducing assembly complexity.

The close-coupled turbine-generator assembly provided a compact, efficient design

The close-coupled turbine-generator assembly provided a compact, efficient design

Another important design feature was the stand, which needed to support the weight of the turbine-generator and the other members that make up the air flow path. Finally, the vibrational behavior of the entire structure needed to be assessed, including rotordynamics.

.webp?width=600&height=450&name=Designing%20an%20Oscillating%20Water%20Column%20Wave%20Energy%20Converter8(1).webp) The assembled Wave Swell Energy UniWave® getting ready for testing

The assembled Wave Swell Energy UniWave® getting ready for testing

The Wave Swell Energy UniWave® out on the water producing power

The MSI turbomachinery design package was passed on to Wave Swell, who made tweaks based on additional manufacturability and assembly considerations. Wave Swell then completed detailed manufacturing drawings, manufactured the prototype, and deployed it near King Island for testing and evaluation.

A sneak peek inside the Wave Swell UniWave® - "you gotta love that!"

If you would like help making your turbomachinery concept a reality, Contact Us and we would be happy to help you.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Design, Analyze, and Build a Prototype Radial Gas Turbine

MSI was tasked with designing a prototype 20 hp high speed radial gas turbine generator to operate at 40,000 RPM with R-134a as the working fluid.

Case Study

Design of Oil Extraction Gear Pump & Motor

MSI was contracted to design a down-hole, multi-set external gear hydraulic motor – pump unit.

Case Study

Axial Hydro Turbine Design and Test

MSI was tasked with designing a subscale (1/6th) axial hydro-turbine utilizing a belt system to drive a generator.