Contact Stress Analysis of an Artificial Knee

The longevity of an artificial knee replacement depends on many factors. Although great strides have been made in improving the wear performance of ultra-high-molecular-weight polyethylene (UHMWPE), tibial insert wear is still one of the most important failure mechanisms. To improve the wear characteristics, designs are sought that reduce the contact stress between the femoral and tibial components. Lower contact stress can be achieved by increasing the amount of shape conformance between the femoral and tibial components. Since there is a trade-off between wear performance and kinematic performance, it is paramount that the contact stress distribution is well understood for any given design.

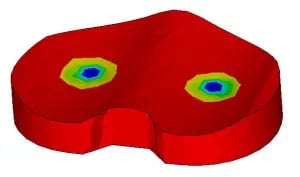

Compressive stress distribution on tibial insert.

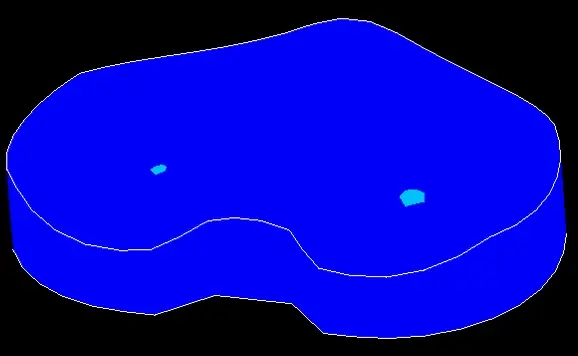

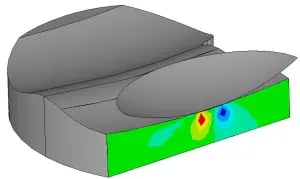

MSI has investigated a particular knee replacement design for contact stress. The general surface-to-surface frictional contact algorithms of the ANSYS Multiphysics finite element code were utilized. Higher-order curvilinear elements were employed to model the contacting surfaces. The elastic-plastic material behavior was also incorporated into the UHMWPE tibial insert. The lower surface of the tibial insert was held fixed in space while the femoral component was forced to move according to typical activities including gait-cycle motion. Both surface and subsurface stresses in the UHMWPE were calculated and animated throughout the range of motion. Contact areas were also calculated at specific points within the load cycle. These analytically predicted contact areas are typically found through experimental testing using pressure sensitive films. The accuracy of these films varies, and the mere presence of the film may have an artificial effect of increasing the contact area.

Animation.

Based on the predicted stresses and contact areas, a modification to the articulating surface shape was proposed. The stress results are currently being coupled directly to a wear law so that volumetric wear can be estimated and compared for the existing design and the new proposed shape.

Subsurface shear stress distribution on tibial insert surface.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.