Stripper Tower & Associated Pipe Vibration Problem Solved

Condition Monitoring Piping 180’ Above on a Stripper Tower

Condition Monitoring Piping 180’ Above on a Stripper Tower

MSI conducted vibration and strain gauge testing of a rerated CO2 stripper tower piping in the US-Mideast. The main purpose of the testing was to detect the cause of fretting on newly installed piping at an elevation of 180’.

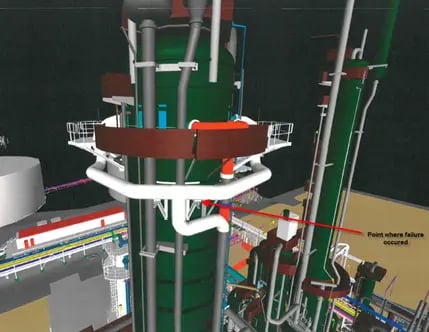

Picture of the piping and failure location that lead to condition monitoring and FEA.

MSI performed specialized vibration testing that included experimental modal analysis (EMA), continuous monitoring, operating deflection shape (ODS) characterization, and installed strain gauges to identify the root cause of this non-related rotating machinery vibration issue. Based on the as-measured pipe dynamic behavior, the fretting and pipe support weld failure was a result of flow-induced broadband excitation increasing the piping vibration amplitude at lower frequencies, and exciting piping natural frequencies.

- Problem Statement (Challenge)

- CO2 Stripper Tank 36” Diameter Piping 180' above ground level.

- US-Mideast

- The piping had experienced fretting at a support interface that led to a chemical leak.

- Work Performed

- Condition Monitoring, Operating Deflection Shape (ODS), Finite Element Analysis (FEA), Strain Gauges on Piping

- Results/ Solution

- After discussion with the piping engineers, it was concluded that the flow-induced broadband excitation was a result of an unexpected phase change of the fluid inside of the pipe. The saturated liquid was flashing into vapor before entering the tank. The flash provided enough energy to the system at low frequencies to excite the lower natural frequencies of the piping.

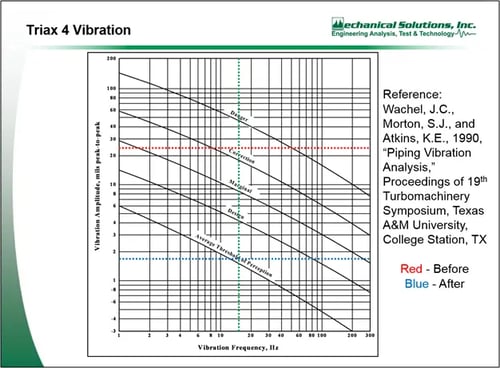

- The addition of the piping baffles (multi-orifice plates), on both sides of the piping just before entering the tank, prevented the fluid from flashing and eliminated the problematic broadband random excitation. The overall level and the frequency spectra of the pipe vibration, before and after the piping baffle modification, indicated that the resonance issue that led to the piping fretting and weld crack at a pipe support has be resolved permanently. The plant was able to finish the uprate project and subsequently increase their profits.

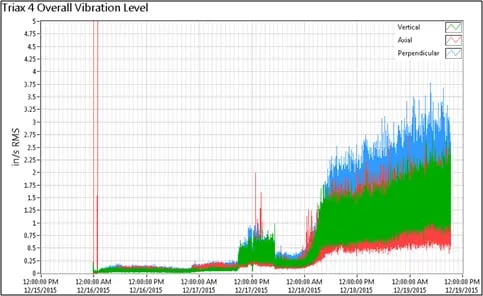

Overall vibration data collected before the baffles modification.

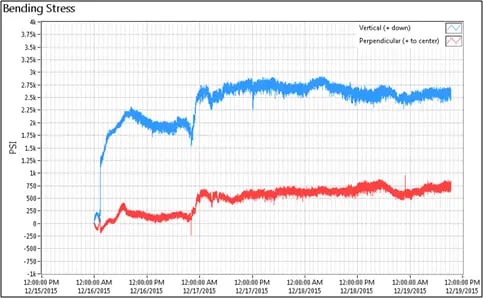

Pipe stress data collected before the baffles modification.

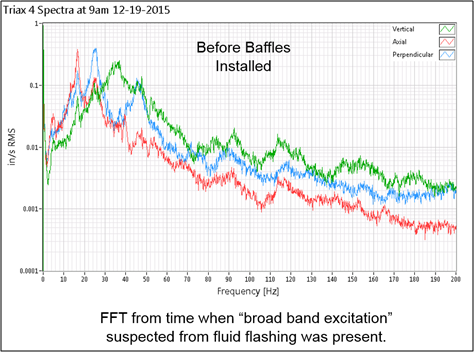

Plot of FFT data collected on the piping before the baffles modification.

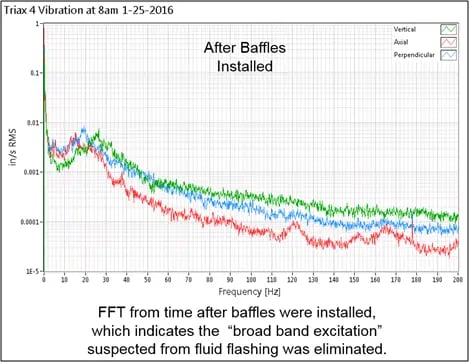

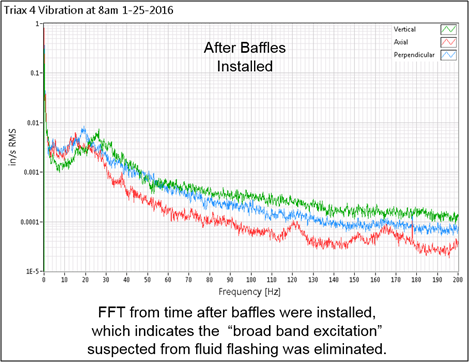

Plot of FFT data collected on the piping after the baffles modification.

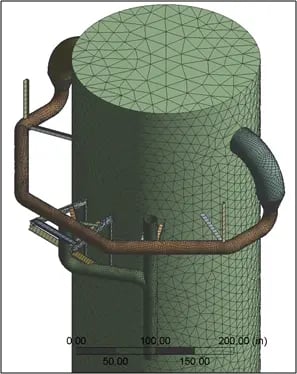

FEA model mesh created by MSI.

Change in pipe displacement at 17.5 Hz before and after the baffles modification.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Solids Handling Pump Repetitive Failure of Bearing and Seal

An engineering construction firm needed help in determining the root cause for the repetitive pump bearing and seal failures of a solids handling pump and to provide a solution to eliminate the issue.

Case Study

Design Assessment Mitigates Risk

A design assessment was carried out in an effort to prevent potential premature bladed disk and impeller fatigue failures of three newly installed critical compressor trains.

Case Study

Development of a Prototype Vacuum Blower

A major aerospace equipment supplier/manufacturer needed to design and prototype an FAA-approved vacuum generator for use on commercial aircraft.