Alarming Sounds From Wastewater Digester Complex Compressor

MSI Troubleshooting Consultants Determine Compressor Beating Phenomena Responsible for Piping Vibration, and How to Fix

Alarming Sounds From Wastewater Digester Complex Compressor: Pipe Vibration

MSI troubleshooting engineers conducted specialized vibration testing of digester complex compressor piping in the US-Midwest. The main purpose of the testing was to find the root cause for elevated noise levels that made a loud chattering sound.

|

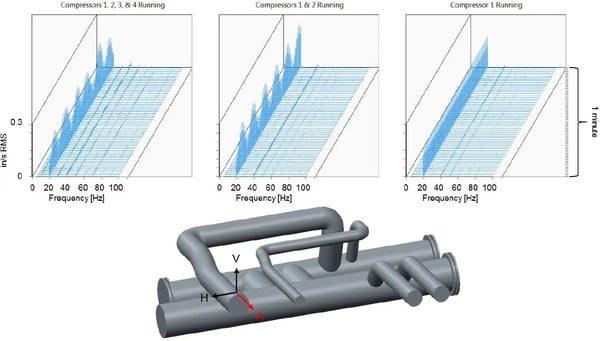

Testing indicated that a beating phenomena was occurring because of slight variations in the compressor speeds, causing the pressure excitation to rise and fall in severity as the pulsations from each compressor drifted in and out of phase with each other |

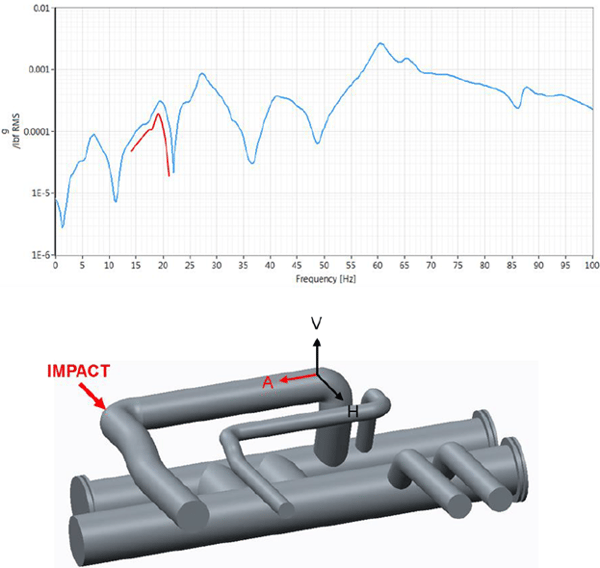

MSI troubleshooting consultants performed specialized vibration testing that included experimental modal analysis (EMA), continuous monitoring, operating deflection shape (ODS) characterization, and collected motion magnified video data using VibVue®. This testing indicated that a beating phenomena was occurring because of slight variations in the compressor speeds, causing the pressure excitation to rise and fall in severity as the pulsations from each compressor drifted in and out of phase with each other. While acoustic resonance was not contributing to the problem, impact testing revealed a mechanical natural frequency in the piping system near the pressure pulsation frequency of 20 Hz that was exacerbating the problem.

Resonant excitation of this natural frequency resulted in large deflections of a localized section of pipe during times when the compressors’ pulsations reinforced each other, as compared to reduced pressure excitation during times when the compressors' pulsations canceled each other out. Addressing the motion of this particular section of pipe was key to eliminating the nuisance noise.

MSI recommended the following be done in order until the compressor piping problem was resolved:

-

- Inspect and adjust piping hangers, since they were loose or unloaded during testing

- Add mass to shift the structural natural frequency

- Add tuned vibration absorbers

- Add Variable Frequency Drives (VFDs) to positively control compressor speeds

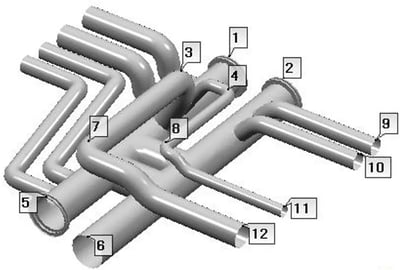

Locations of the twelve triaxial accelerometers used

Locations of the twelve triaxial accelerometers used

Vibratory response of the pipes at the indicated measurement location and direction

Vibratory response of the pipes at the indicated measurement location and direction

Frequency response function plot of a modal impact test point

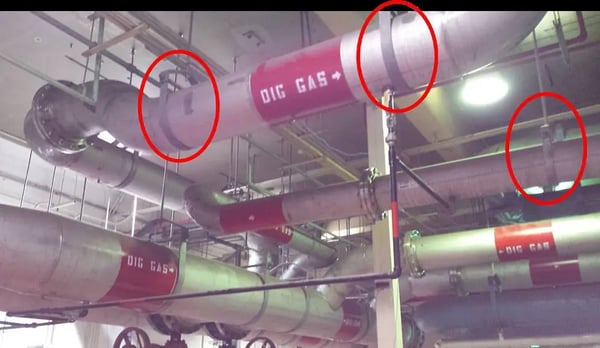

Pipe hangers of particular importance to contain the motion exhibited during noisy periods

Pipe hangers of particular importance to contain the motion exhibited during noisy periods

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.