Raw Water Pumps Experience High Vibrations And Failures

It was reported by a construction company that four raw water vertical turbine pumps had severe vibration issues as well as catastrophic failures since the water treatment plant was placed into service in September 2010. MSI was called to help at the end of April 2015.

Problem Statement (Challenge)

-

- What (type of machine): Raw Water Vertical Turbine Pump

- Where (State/ Country): Kentucky

- Why (problem/reason): A construction firm needed help in determining the root cause for the high vibration amplitude of four vertical turbine pumps and to provide a solution to mitigate this issue. The site identified that the pumps had experienced periods of severe sub-synchronous vibration (SSV). Visual inspections (by others) revealed severe damage to the pump impellers, volutes, shafts, shaft bearings and (collapsed) bearing spiders. MSI was called to conduct specialized vibration testing on the pump systems and help avoid dealing with future problems.

- Work Performed

- Results/ Solution

- Findings: The elevated sub-synchronous vibration (SSV) measured at the motor and the bowl assembly and the repetitive failure of the below-ground structure of the RWPs was due to resonance of a below-ground dominated structural natural frequency excited by a rubbing/ impact phenomenon. This excitation source typically occurs at 1/3x rpm and with less activity at its harmonics (i.e. 2/3x rpm). Based on MSI’s testing, one RWP was more susceptible to resonance due to a below-ground mode (3rd bending or “S” shape mode) at 5.25 Hz only having a 0.5% separation margin from the 1/3x rpm excitation source. In addition, this pump consistently exhibited this SSV response. The two other pumps indicated higher natural frequencies, and therefore higher separation margins with respect to this excitation source.

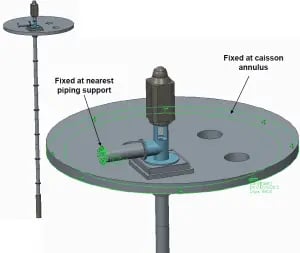

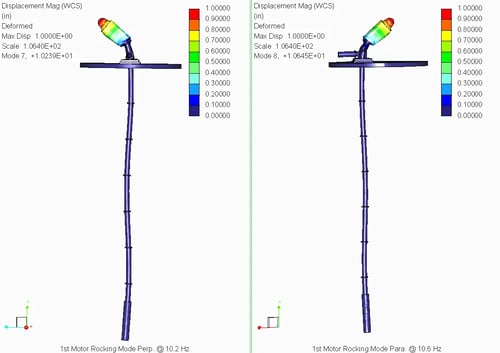

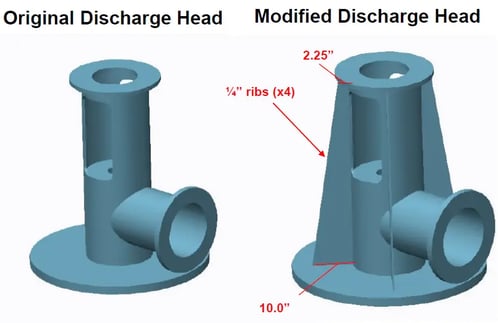

- Impact: The findings led MSI to recommend speed ranges where the pumps should not operate until structural modifications were made. MSI recommended a clean water flushing system for the bearing in order to avoid foreign material accumulating between the shaft and the bearings. Another recommended approach considered concurrently was to modify the pump designs such that below-ground natural frequencies achieved larger separation margins from the running speed excitations. Two pumps indicated a moderate vibration response from 40% to 44% of running speed. This excitation was attributed to a fluid whirl within the column. To reduce this vibration, a single longitudinal internal rib (swirl break) along the column pipe was considered. MSI was hired to create an FEA model which was calibrated to the field data to test potential modifications. The results stated that decreasing the overall pump length by 5 ft or 10 ft would not result in a negative impact for the system and that the addition of ribs on the discharge head would help solve the mode in resonance near 40% to 44% of running speed.

Vertical turbine pump instrumented with proximity probes, laser tachometer, RF telemetry, and a torque strain gauge

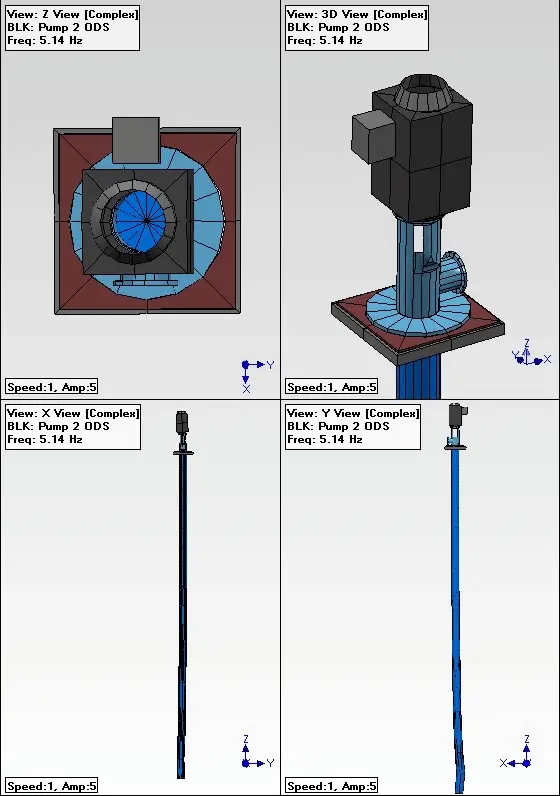

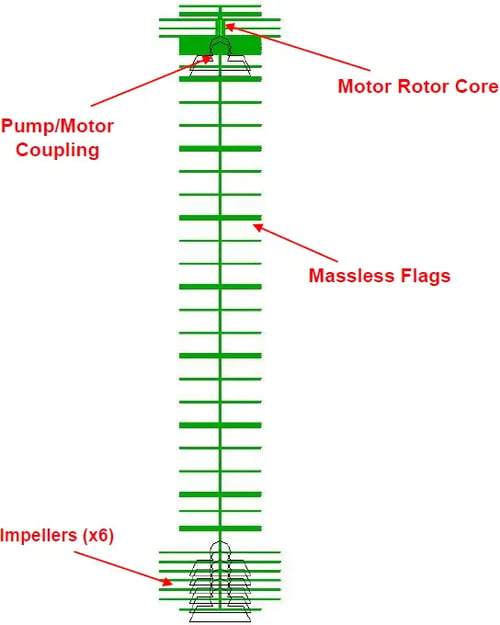

Finite Element Analysis Model of One Pump

Results of the modifications to the discharge head

Modifications made to the discharge head to resolve issue

Torsional FEA model put together to identify potential problems

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

New Orleans Flood Control Pumping Stations Vibration Analysis

MSI was recommended to analyze flood control pumping station system dynamics, including evaluation of the platform design with regard to vibration.

Case Study

Water Treatment Plant Pumps Fail Vibration Specification During Commissioning

A contractor putting together a water treatment facility encountered vibration issues with various pumps during commissioning.

Case Study

Newly Installed Water Treatment Plant Pumps Cavitating & Vibrating

A county water treatment plant heard “cavitation-like noise” from their newly installed pumps and called MSI for help.