Nuclear Plant Has Identical Motor Generator Sets Vibrating Differently

Nuclear Plant Has Identical Motor Generator Sets Vibrating Differently: Two identical MG sets used in a nuclear plant were vibrating differently, one above allowable limits. MSI performed field testing on this Rotating Machinery Vibration issue to discover that the rubber mounts were at fault and an immediate shut down was avoided.

- Problem Statement (Challenge)

- What (type of machine): Nuclear Plant Motor Generator Flywheel Set

- Where (State/ Country): Louisiana

- Why (problem/reason): Identify cause of high vibration on a critical Motor Generator set of a Nuclear Plant

- Work Performed

- Results/ Solution

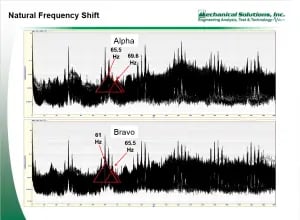

- Findings: Resonance was identified with 2xN. This was due to a bolted connection stiffness decrease (soft foot) and a larger than normal rubber mount deflection.

- Impact: The findings and proposed modifications led to the installation of temporary adjustable wedges under the skid to compensate for the lack of stiffness in the rubber mounts. This was done as an immediate step to reduce vibrations of the generator until the unit can be secured and root causes properly addressed. The plant did not need to shut down for an unexpected outage.

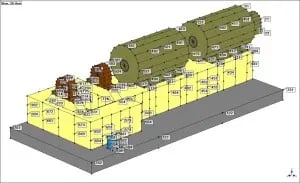

lags in picture show ODS points acquired.

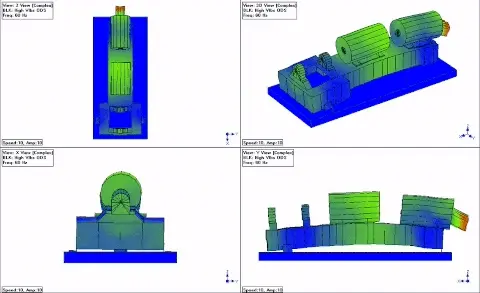

Click image to animate.

Wedge inserted under baseplate to shift natural frequency.

FFT plot showing the natural frequency difference between MG sets.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.