Hydro Turbine Gearbox Failure Analysis And Repair

When a hydro turbine gearbox failed, MSI was brought in to determine the extent of the damage and provide an engineered solution to get the turbine generating power as quickly as possible.

MSI was tasked with a) determining the impact of damage from the gearbox pin backing out of the bore, and b) providing a recommended fix.

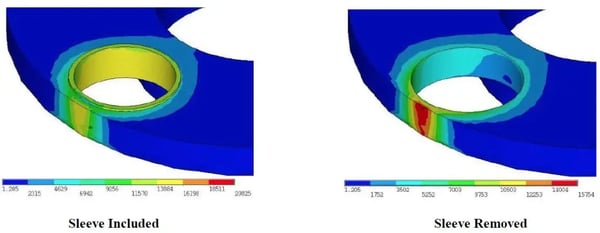

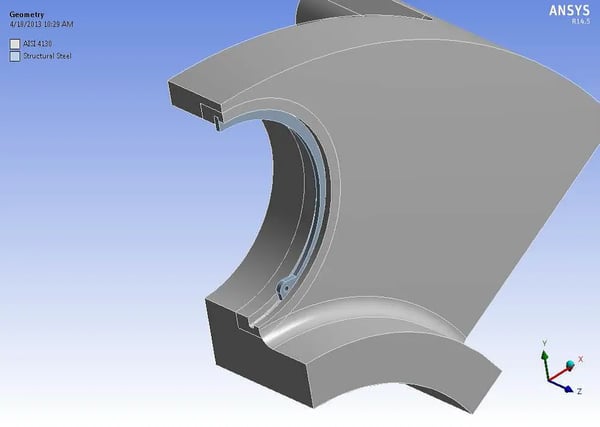

The gearbox failed when a shaft pin for one of the planetary gears backed out of its mounting bore in the carrier shaft, causing damage to the surrounding area. Based on limited documentation, MSI performed valuable finite element analysis (FEA) of the stresses involved for the damaged area, and both the worn bore and a newly sleeved bore. While the damage was deemed to be minor, MSI recommended a sleeve insert would successfully restore pin fit and gear function without jeopardizing the integrity of the system.

Stress analysis indicated the recommended shaft sleeve would restore pin fit and maintain the function of the gearbox component.

After implementing the recommended repair, the customer discovered a crack in another location of the carrier shaft. MSI was then asked to determine if the crack was repairable or if the carrier shaft needed to be replaced. An ultrasonic survey was performed to determine the depth and extent of the crack, and repair options were considered. Based on this analysis, the carrier shaft was deemed non-repairable.

The customer required analysis of repair feasibility and options for a large crack discovered in the carrier shaft.

Given the lead time associated with a) delivery of a new carrier shaft from the OEM, and b) fabrication of a new carrier shaft from casting, the customer asked MSI to rapidly design a replacement carrier shaft from forgings and flat plate.

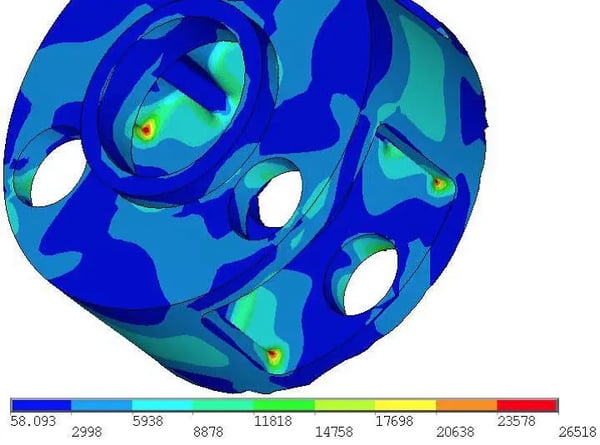

MSI embarked on a design with several parties involved, and performed a subsequent thorough, yet urgent, analysis of the replacement carrier shaft. Stress and fatigue analysis showed that the newly designed replacement would surpass the original design, given MSI’s recommended material selections and welding guidelines.

Analysis of the new design indicated improvements in equivalent stress, but also showed the importance of material selection and weld performance.

After the customer successfully implemented the replacement carrier shaft and got the system making hydropower again, MSI was tasked with solving the planet gear shaft pin failure, where the pin would axially slide out. After assessing the current arrangement, a retainer ring design was ultimately selected, providing an elegant solution to a persistent, costly problem.

The retainer ring provided the retention that the shaft pin required without compromising the overall system.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.