Boiler Feed Pump Optimization to Reduce Cavitation

Accurate CFD modeling, validated by real-world results, provides the basis for a redesigned impeller that significantly reduces cavitation

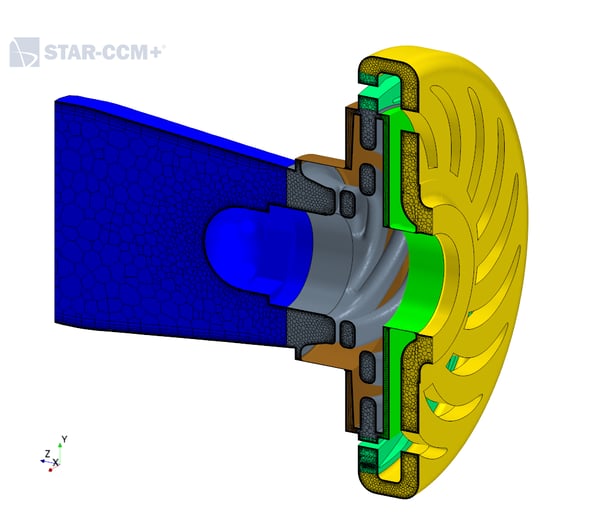

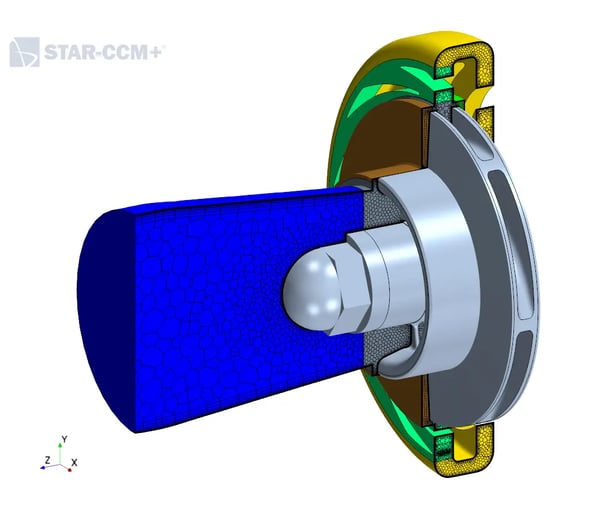

MSI fluids engineers were tasked by an OEM to investigate cavitation performance of the first stage in a boiler feed pump design. The first stage, consisting of a suction, an impeller, a diffuser and a return channel, was modeled in Simcenter STAR-CCM+.

Due to MSI’s considerable computational resources, a full 360° model of the stage, including the secondary passages, was analyzed in a transient manner. The ability to do transient Computational Fluid Dynamics (CFD) analysis, where the mesh of a rotating domain is moved with respect to the stationary components at every timestep, is especially important to resolve problems that arise due to cavitation, because cavitation is an inherently unsteady and unstable phenomenon.

Comprehensive 360° CFD model of the stage with secondary flow passages and rotating components provides accurate modeling as the basis for optimization

Comprehensive 360° CFD model of the stage with secondary flow passages and rotating components provides accurate modeling as the basis for optimization

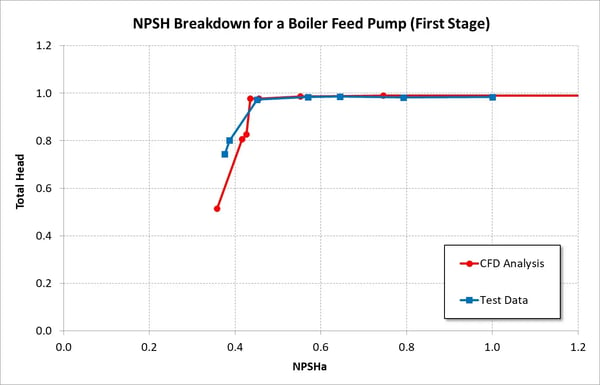

Using transient CFD analysis at multiple NPSH points, where each point was analyzed for as many as seventeen revolutions, MSI fluid dynamics engineers constructed a predicted breakdown curve for the first stage that matched extremely well to a test curve later revealed by the customer.

Accurate, high-fidelity unsteady modeling provides useful data that correlates to real-world results

Note the strong presence of cavitation with the red sections trailing the impeller vanes

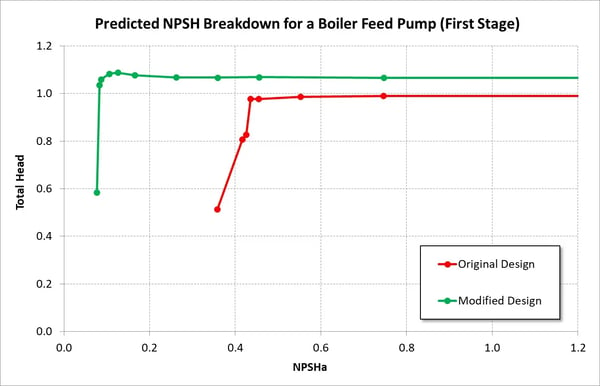

MSI then created an optimized design for the first-stage impeller, and constructed another breakdown curve following the same methods. This modified design is predicted to both improve the pump head and greatly improve the cavitation performance of the first stage.

Performance is substantially improved with the modified impeller design

Performance is substantially improved with the modified impeller design

The unsteady model of the MSI-optimized design demonstrates drastically reduced cavitation for better performance

MSI has several examples of our CFD data correlating extremely well to real-world test data. If you are interested in learning more, we recommend this paper published in the Journal of Physics.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.