Water Treatment Plant Pumps Fail Vibration Specification During Commissioning Of An RAS Pump

Pumps Fail Vibration Specification During Commissioning Of An RAS Pump: A contractor putting together a water treatment facility for a large city in Colorado encountered vibration issues with various pumps during commissioning. An independent opinion was required after multiple failed attempts by the OEM to fix the problem.

- Problem Statement (Challenge)

- What (type of machine): Primary Effluent (PEP), Return Activated Sludge (RAS), and Secondary Waste Activated Sludge Pumps (SWAS) in a Water Treatment Plant

- Where (State/ Country): Colorado

- Why (problem/reason): A contractor putting together a water treatment facility for a large city in Colorado encountered vibration issues with various pumps during commissioning. An independent opinion was required after multiple failed attempts by the OEM to fix the problem.

- Work Performed

- Results/ Solution

- Findings: The root cause for the elevated vibration in the PEPS pumps was a pump bearing frame and shaft lateral resonant condition within the operating speed range at vane passing frequency. The RAS pumps had the first shaft lateral bending mode excited by vane pass frequency near the upper end of the speed range. The SWAS pumps suffered from excessive flexibility between the bearing frame and the stuffing box leading to a bearing frame natural frequency in resonance, and also piping structural natural frequencies within the running speed range.

- Impact: The contractor presented MSI’s findings and recommendations to the OEM to try and find mutually agreed upon solutions to the problem. The contractor avoided costly delay penalties by finding the root cause and not continuing to pursue the cut and try method.

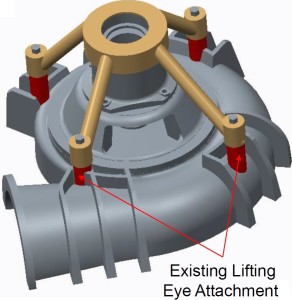

PEP suggested modification

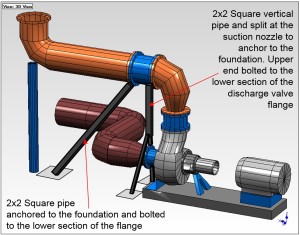

MSI suggested discharge piping bracing

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

New Orleans Flood Control Pumping Stations Vibration Analysis

MSI was recommended to analyze flood control pumping station system dynamics, including evaluation of the platform design with regard to vibration.

Case Study

Water Treatment Plant Pumps Fail Vibration Specification During Commissioning

A contractor putting together a water treatment facility encountered vibration issues with various pumps during commissioning.

Case Study

Newly Installed Water Treatment Plant Pumps Cavitating & Vibrating

A county water treatment plant heard “cavitation-like noise” from their newly installed pumps and called MSI for help.