VTP Gear Problem with Vibration Absorbers

Mechanical Solutions, Inc. (MSI) was contracted to solve excessive vibration problems on four newly installed 3-stage vertical turbine pumps at an oil platform fire pump station. All of the units are driven by diesel engines with a right-angle gear operating at a constant speed (28.75 Hz). A 10-blade fan and heat exchanger at the top of the gearbox provides gearbox cooling. The customer reported that all the pump/gear sets had been operating with high overall vibration levels exceeding the specification limit of 10 mm/s RMS (0.40 in/s RMS).

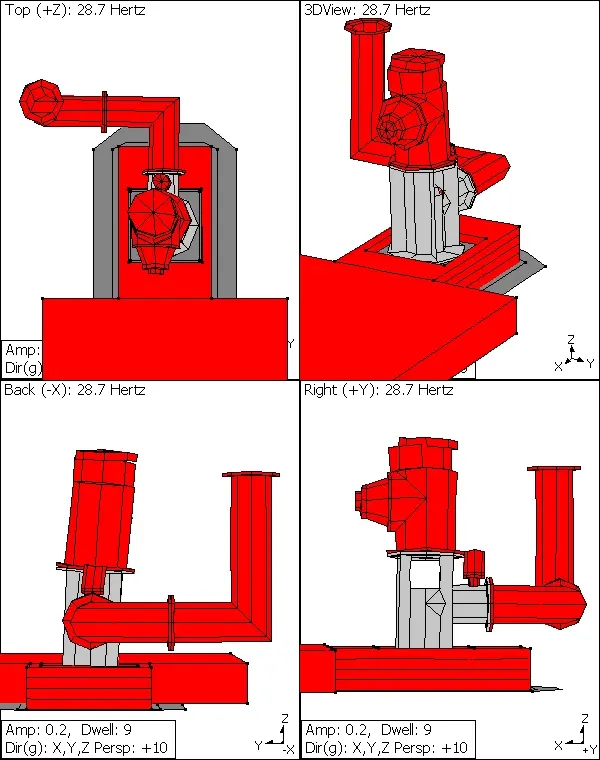

MSI collected detailed natural excitation vibration data on all components of each pump, gearbox, and heat exchanger including the nearby floor, baseplates, engines, and discharge piping. MSI uses a specialized operating forced response vibration technique that allows the data to produce very detailed animated operating deflection shapes (ODS) of the pump system. The ODS animation shows the relative motion of various system components in an exaggerated fashion to help efficiently identify the problem's root cause(s) (Figure 1). MSI also performed a propriety type of impact modal testing while the units were operating to determine the natural frequencies and mode shapes.

Figure 1.

Figure 1.

The pump/gearset had an overall vibration amplitude, 34 mm/s RMS, in the direction perpendicular to the pump discharge pipe. The reason was inherent flexibility on the aluminum heat exchanger between the cap on the vertical gearbox and the gearbox itself (see lower right quadrant of Figure 1). The heat exchanger moved out of phase within the gearbox. MSI installed and adjusted a vibration absorber on this pump in order to reduce the vibration at 1x running speed. The filtered vibration at a running speed of 28.75 Hz was reduced from 32.4 mm/s RMS to 0.76 mm/s RMS in the perpendicular direction and from 12.8 mm/s RMS to 7.1 mm/s RMS in the parallel direction.

There was also high frequency vibration plaguing these pumps, which remained a problem after the 1 x RPM vibration was solved. The source of the high frequency vibration of the pumps was found to be looseness in the gear housing assemblies, where gear housing parts were acting as impact hammers exciting all the natural frequencies in the system in all directions over a broad frequency range.

Figure 2. MSI Engineer stands next to the equipment in the field

In order to minimize the separation/ looseness between the gear/ pump assemblies, MSI recommended the following improvements:

- Install steel helicoil thread inserts in all bolted joints in the heat exchanger to improve the attachment of the finger guards and the heat exchanger.

- Install resilient (high spring-back after compression) gaskets between aluminum parts and aluminum steel parts to avoid separation and impacts.

- Fan cover and heat exchanger bolts should be installed by using conical washers to improve retention of preload between components.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Troubleshooting a Pipeline Renewable Diesel Screw Pump

Elevated vibration levels were causing a pipeline company screw pump problems.

Case Study

Petrochemical Ammonia Recip Compressor Piping Troubleshooting

Excessive motion by the discharge piping of a petrochemical ammonia reciprocating compressor startled the operators.

Case Study

Oil Tanker Pumping Station Screw Pump Troubleshooting

Troubleshooting a new oil tanker pumping station in Colombia consisting of 4 screw pumps. Specialized testing revealed that piping natural frequencies were to blame.