Upgraded Pump Station Exceeds Overall & Pipe Vibration Limits

A recently upgraded pipeline crude oil pump station in Texas was experiencing high vibration levels on its pumps, as well as high pipe vibration. MSI set out to diagnose these VFD controlled units using specialized vibration testing methods.

- Problem Statement (Challenge)

- What (type of machine): Pipeline Crude Oil Horizontal Split Case Centrifugal Pump

- Where (State/ Country): Texas

- Why (problem/reason): Recently upgraded pipeline pump station exceeds the Hydraulic Institute Standard vibration limits on both pumps.

- Work Performed

- Results/ Solution

- Findings: Resonance was identified with vane pass response. This was due to various structural suction piping, discharge piping and bearing housing natural frequencies.

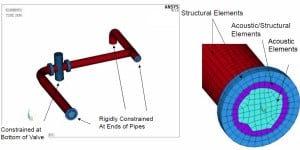

- Impact: The findings led to the installation of a modified bearing housing to increase stiffness and therefore increase the structural natural frequency above the vane pass frequency excitation range. Piping modifications were analyzed using a Finite Element Analysis calibrated to the data collected on site to develop a solution with a greater chance of success upon implementation.

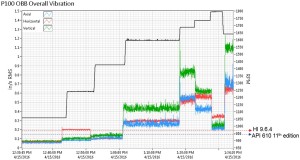

Overall vibration vs. speed trend plot.

Click image to animate. Bearing housing problem mode shape.

ANSYS pipe acoustic FEA model.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Troubleshooting a Pipeline Renewable Diesel Screw Pump

Elevated vibration levels were causing a pipeline company screw pump problems.

Case Study

Petrochemical Ammonia Recip Compressor Piping Troubleshooting

Excessive motion by the discharge piping of a petrochemical ammonia reciprocating compressor startled the operators.

Case Study

Oil Tanker Pumping Station Screw Pump Troubleshooting

Troubleshooting a new oil tanker pumping station in Colombia consisting of 4 screw pumps. Specialized testing revealed that piping natural frequencies were to blame.