Remote Vibration Performed In SE Asia Steam Turbine From The USA

A power plant in Southeast Asia experienced high vibration and cracking in the exhaust hood of a large steam turbine. The avian flu outbreak in 2005 severely limited travel to the area. Typically, fixing turbomachinery vibration problems involves several steps. First, it requires traveling to the machine's location and gathering vibration data.

Once you have collected the necessary information, you can analyze it at the office. Finally, based on your analytical findings, you can offer a solution to address the vibration problems. In this particular case, MSI agreed to use a new remote vibration problem-solving method to meet the customer's needs.

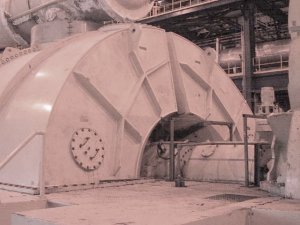

Figure 1. Exhaust hood cracking created a reliability and safety concern.

At first, MSI shipped sophisticated test instruments such as vibration signal analyzers, accelerometers, and dynamic pressure transducers to the job site. MSI provided an IP phone and camera to enable audio and visual communication.

MSI oversaw the installation of the test hardware from 12,000 miles away. Local workers at the plant aided MSI in problem-solving. These workers received real-time instructions from MSI staff in New Jersey using an early version of the Distance Communication Maintenance System. MSI staff was able to remotely control the FFT 40‑Channel analyzer through broadband internet communication.

The vibration data that was remotely collected allowed the development of a model at MSI's USA offices. MSI compared the FEA results to the test data to analyze possible solutions. The suggested fixes were analyzed, and the structural modifications were confidently implemented.

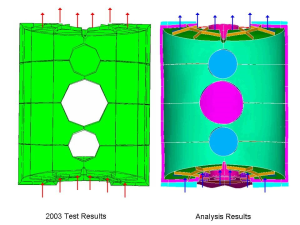

Figure 2. Remote test data applied to computer generated model (Left) vs. FEA analysis results (Right). Testing model motion is slightly more exaggerated than the FEA model motion

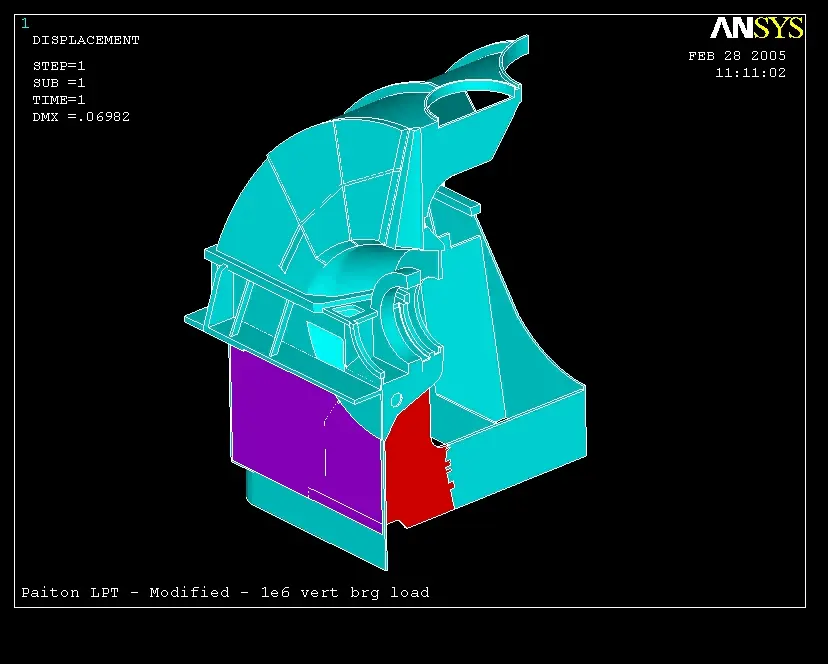

Figure 3. FEA demonstrating turbine casing deflection.

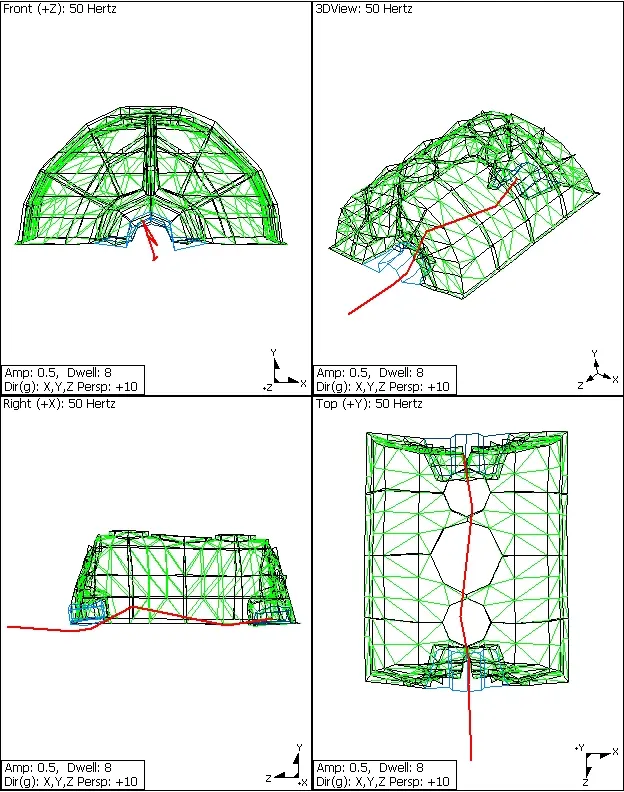

The test data and FEA showed that the exhaust hood vibrates at around 50 Hz with synchronized motion at both ends. Figure 4 shows the movement of the natural frequency. The natural frequency of the S-shaped rotor, which was also around 50 Hz, was linked to this structural frequency. The rotor mode drove the bearing housing, which also drove the motion of the exhaust hood casing.

Figure 4. Operating Deflection Shape (ODS) and modal test data showing exhaust hood and shaft motion.

Follow-up testing performed on-site by MSI staff confirmed that the remote test data and FEA were accurate. MSI strengthened the exhaust hood by adding more support ribs and attaching thick metal plates to the ends. This reduced the vibration amplitude and stopped the cracking. MSI avoided costly trial-and-error problem-solving, and the remote approach allowed MSI to respond swiftly and minimize travel-related costs.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.